How to choose the ball loading and loading ratio of ball mill? How to determine whether the ratio of loaded ball is reasonable?

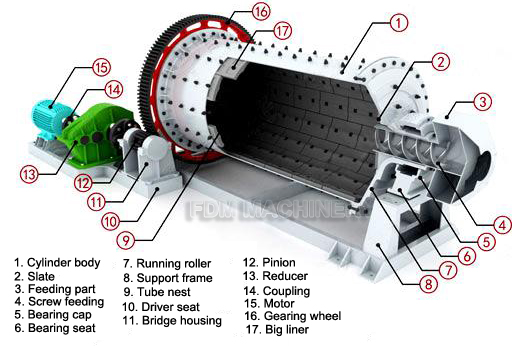

Ball mill is one of the commonly used equipment in mineral processing equipment. For ball mill, reasonable ball loading not only affects the improvement of grinding efficiency and productivity, but also relates to the service life of ball mill. Therefore, it is very important to master the reasonable ball loading quantity and the ball loading ratio of the ball mill in the process of using the ball mill.

Selection of ball loading

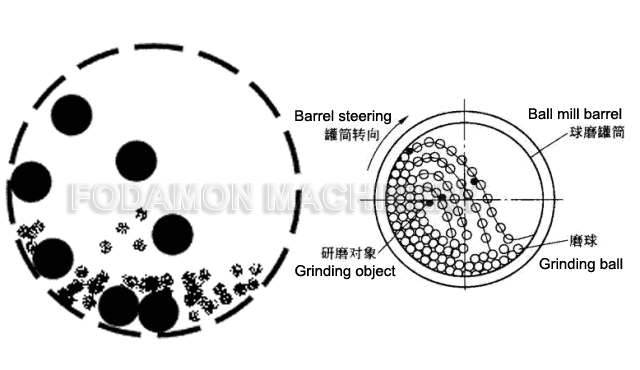

When a ball mill works, its efficiency generally depends on the sum of work done by each ball (number of impact times and impact force). Therefore, it is necessary to give full play to the efficiency of each steel ball, so that the steel ball moving along different tracks (trajectories) can not collide as much as possible.

When the speed of the ball mill is fixed and the loading capacity is 30%, the movement of the ball is mainly sliding, but the inclination has begun to appear; when the loading capacity exceeds 40%, the movement of the ball is mainly inclined; when the loading capacity reaches 50% of the total capacity of the cylinder, because the surface of the ball group is just on the diameter of the cylinder, the reason is that And prone to tilting. Tilting current is needed for ball mill production, so it is more appropriate to load balls between one third and one half, and the most ideal is close to one half.

According to the actual results of laboratory, when the filling quantity of steel balls in cylinder is 40%, the output is the highest, while the filling rate of steel balls in production is about 35%, that is to say, keeping the volume of steel balls is lower than that of the horizontal center line.

Selection of loading ratio

To determine the appropriate ball loading quantity, we need to choose the appropriate ball loading ratio. Consideration factors include the size of steel ball, ball diameter series, the proportion of balls of various specifications and so on. Rational gradation of steel balls is the key to meet the crushing requirements, which directly affects the grinding efficiency and ultimately affects the output of ball mills.

The main function of steel ball in ball mill is to break the material by impact, and it also plays a certain role in grinding. In order to determine the gradation of steel balls, besides the factors such as the size of ball mill, internal structure of ball mill and product fineness requirements, the characteristics of grinding materials (grindability, particle size, etc.) should also be considered. Generally, the following principles should be followed:

- The steel ball must have enough impact force, the hardness of the material is large, and the diameter of the steel ball is large.

- On the premise of ensuring enough impact force, reduce the diameter of abrasive body as far as possible and increase the number of steel balls to increase the number of impact times on materials, so as to improve the grinding efficiency;

- The steel ball should have the ability to control the material flow rate to ensure that the material has enough residence time in the mill to be fully crushed.

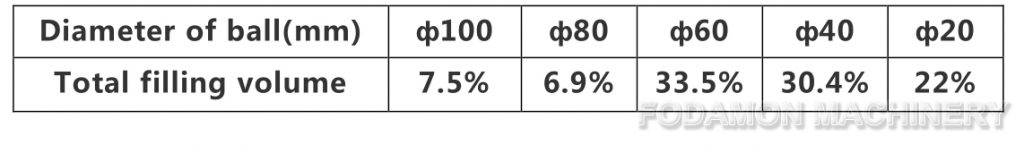

When the ball mill is used for pulverizing material, the ball milling ratio of the following steel balls is the highest:

In production, the two-stage ratio and the multi-stage ratio are more common. Generally, the multi-stage ratio follows the principle of “less at both ends and more in the middle”. The so-called two-stage distribution method is to use steel balls with two different sizes and larger diameters to carry out the gradation.

The theoretical basis is that the voids between big balls are filled by small balls to fully increase the packing density of steel balls. The big ball can break the material by impact, improve the impact ability and impact times of the mill, which accords with the functional characteristics of the grinding body; while the small ball can fill the gap between the big balls, increase the accumulation density of the grinding body, so as to control the material flow rate; in addition, the coarse particles in the gap can be squeezed out and placed in the impact of the big ball. In the area.

Generally, coarse ore particles are attacked by large steel balls, and fine ore particles need to be milled by small steel balls, which are too large and not fine, and show as “under-grinding”. On the contrary, too many small balls, large surface area and over-grinding will increase. At the same time, due to too few big balls and insufficient ball strike force, the so-called “over-grinding and under-grinding” will be formed. Therefore, it is very important to determine the size of the maximum and minimum balls correctly for reasonable ball loading and improving grinding efficiency.

Comparison of two stage ratio and multi-stage ratio

The use effect of the two kinds of ball matching is greatly different from that of the material change. The multi-grade ball matching is sensitive to the change of the material, and the output of the ball mill fluctuates greatly. The two-stage ball matching is not sensitive to the change of the material and the output is relatively stable. That is to say, when the grindability of the material is better, the output of the multi-graded ball increases more than that of the two-graded ball; on the contrary, the output of the multi-graded ball decreases more than that of the two-graded ball. Therefore, multi-graded ball is suitable for materials with smaller particle size and better grindability, and two-stage ball is suitable for materials with larger particle size and worse grindability.

Two grading ball method needs to determine the following parameters:

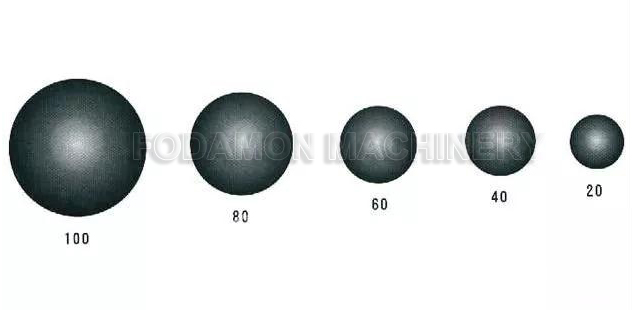

(1) determination of the diameter of the big ball. It depends on the size of the ball mill, the particle size and grindability of the grinding material. Generally, the second level ball diameter in the multistage ball match is the standard. If the maximum diameter of a billiard ball mill is 100 mm in the multi-stage ball distribution, steel balls with diameter of 90 mm should be selected when two-stage ball distribution is carried out.

(2) determination of the diameter of pellets. It depends on the size of the gap between the big balls, that is, the diameter of the big ball. Under normal circumstances, the diameter of the ball is larger than the diameter of the ball 20%-30%.

(3) the ratio of large to small balls. In principle, it should be ensured that the incorporation of pellets does not affect the filling rate of large balls. Ordinary ball occupies 3%-5% of big ball weight.

How to determine whether the ratio of loaded ball is reasonable?

In addition, in actual production, the rationality of loading ratio can be checked from the following two aspects:

- The feed quantity and overflow fineness of the classifier remain unchanged, while the return sand quantity decreases, which indicates that the grinding function of the ball mill is strengthened, and the feed quantity can be increased at this time.

- If according to the results of screening sand returned by classifier, it is found that the increase of ore particles close to the overflow size indicates that the number of small balls is insufficient; on the contrary, if the increase of coarse grains, the number of large balls is insufficient.