An overview of ilmenite ore

- The chemical formula of ilmenite is: FeTiO3, the theoretical component of minerals is FeO47.36%, and TiO2 is 52.64%. If minerals are mainly MgO, they are called magnesia, and MnO is called red titanium manganese ore. Minerals such as magnetite and sulfide are generally found in ore.

2, titanium concentrate usually refers to ilmenite, generally titanium concentrate contains more than 46% TiO2.

- The deep processing of titanium concentrate is mostly for the production of titanium dioxide, which is a white pigment widely used in modern industry. It is used as a light pigment and advanced filler in coatings, paper and plastics, accounting for more than 85% of total titanium consumption. In addition, titanium white is also used as a matting agent for chemical fibers, a filler for rubber products, a catalyst for petrochemicals, and inks. Industrial sectors such as ceramics, glass, welding electrodes, metallurgy, electricians, synthetic gemstones and emerging materials.

Titanium is also produced as an additive to titanium alloys. Titanium and titanium alloys are indispensable materials for the manufacture of modern supersonic aircraft, rockets, missiles and space shuttles.

- The main production bases of ilmenite in China currently include Panzhihua in Sichuan and Chengde in Hebei.

- The ilmenite in the primary ore is often symbiotic with magnetite and vanadium-titanium magnetite. The ilmenite in the sand mine is often produced together with rutile, zircon, monazite and xenotime.

- The general industrial requirements for ilmenite are 10Kg/m3 for the cut-off grade and 15Kg/m3 for the industrial grade.

7, ilmenite crystal is rhombohedron, but the complete crystal form is rare, often irregular granular, scaly, thick plate. It is mostly self-formed until its shape is interspersed among other mineral particles, or it is oriented in the presence of zirconia, titanium hematite, titanium ordinary pyroxene, titanium hornblende and other minerals. product. Color iron black to steel gray. The streak steel is gray or black and contains brown or maroon when it contains hematite inclusions. Semi-metallic luster to metallic luster. Opaque, no cleavage. Sexually brittle, shell-shaped to shell-shaped fracture. Hardness 5-6.5, relative density 4.79, weak magnetic.

ilmenite ore dressing process

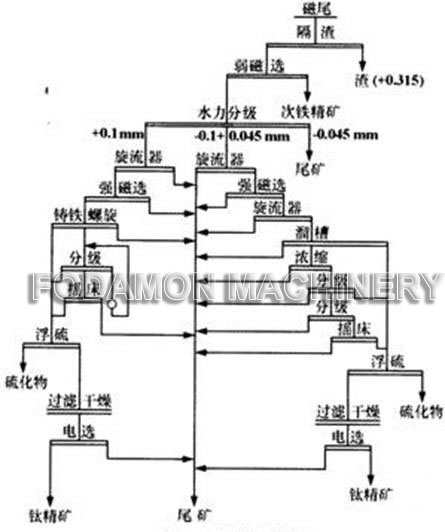

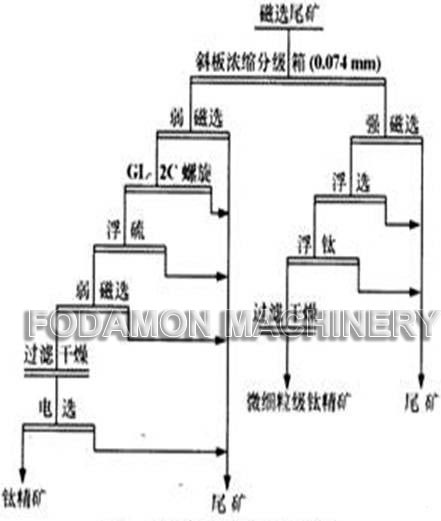

The main beneficiation processes of ilmenite are “re-election-strong magnetic separation—flotation” and “re-election—strong magnetic separation—electric selection (desulfurization before sorting)”, during the beneficiation process It is necessary to strictly follow the classification of grades and adopt different process flows.

The beneficiation equipment used is: inclined plate concentration classifier (graded by particle size), wear-resistant spiral chute (discarding tailings), weak magnetic separator (except strong magnetic mineral), strong magnetic separator (optional ilmenite), floating Machine selection (floating sulfide, floating fine-grained ilmenite), electric separator (selected ilmenite), etc.

Introduction to mineral processing equipment:

1, GL and BLX wear-resistant spiral chute: Fodamon Machinery research and development;

2, electric separator: Fodamon Research Institute’s new generation YD31200-23;

- Select the strong magnetic equipment used in the production of titanium plant: Fodamon vertical loop pulse high gradient magnetic separator;

- Sulphur medicinal system: The main process of selecting titanium with butyl xanthate as collector, 2# oil as foaming agent and sulfuric acid as adjusting agent. At present, the titanium selection process can only effectively recover the +0.074 mm particle size, and the -0.074 mm particle size is basically thrown away from the tailings.

- Overview of the recycling process of fine-grained materials: After the national “seventh five-year”, “eight-five” and “nine-five” scientific and technological research, the process of recycling fine-grained ilmenite (strong magnetic-flotation) was established. During the “Ninth Five-Year Plan” period, through the efforts of Fodamon for many years, a complete set of technology for the recovery of fine-grained ilmenite was formed, and its technology is at the international advanced level and domestic leading level.

- Initial titanium selection process

- Optimized titanium process

Welcome domestic and foreign customers to contact us.