Calcium carbonate is the main component of limestone. Calcium carbonate can be used to prepare calcium carbide, lime calcium powder, limestone, light calcium carbonate, nano-calcium carbonate and other products. It is an important industrial raw material. Calcination is a key process in limestone production. The quality of calcination has a great impact on the quality of subsequent products. Therefore, Fodamon thinks that it is of great significance to study the influencing factors in the calcination process of limestone for improving the quality of products.

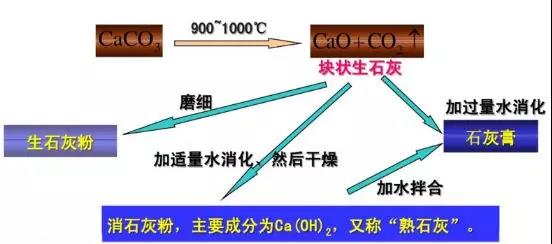

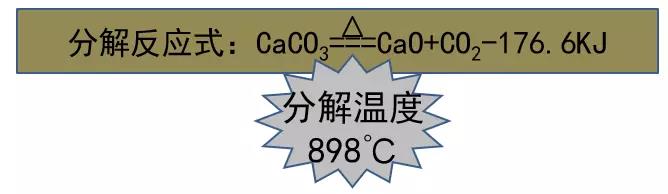

Limestone is a carbonate mineral. After calcination at a certain temperature, calcium carbonate and magnesium carbonate are decomposed and carbon dioxide (CO2) is released. Calcium oxide is the main component of calcined limestone. The reaction equation is as follows:

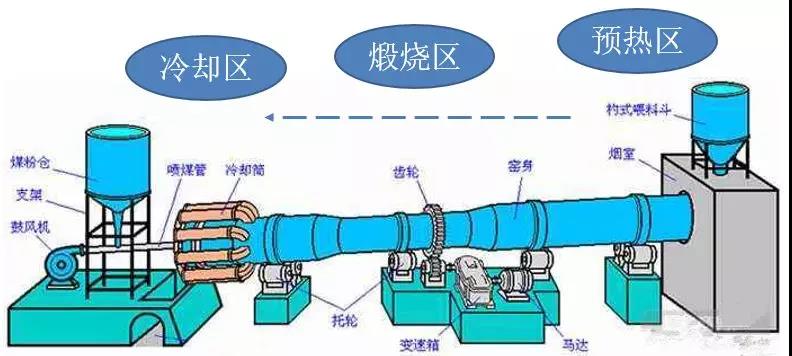

Calcination of limestone is usually carried out in lime kilns. Calcination of limestone is a process of reaction between a series of physical and chemical changes. According to these changes, calcination of limestone in kiln can be divided into three sections:

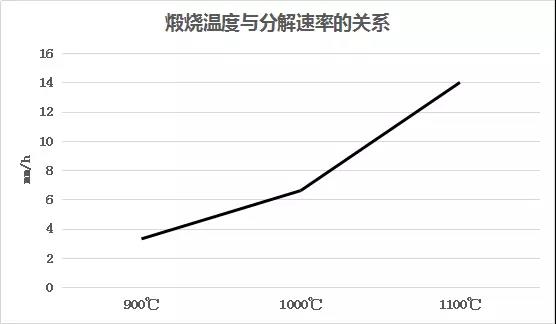

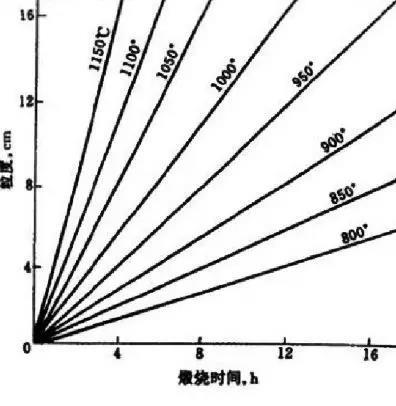

The series of physical and chemical changes of limestone in the shaft kiln is complicated. In actual operation, in order to better control the calcination of limestone in the shaft kiln, to achieve high quality, high yield, stable low consumption, it is necessary to Strict control. 1. Limestone calcination temperature Limestone calcination rate has a great relationship with temperature. At normal pressure, the decomposition temperature of limestone is 898 ° C, and it decomposes rapidly after the temperature is greater than 925 ° C. When the calcination temperature is 900 ° C, the limestone decomposition rate is 3.3 mm / h; 1000 ° C is 6.6 mm / h; 1100 ° C is 14 mm / h. It can be seen that increasing the calcination temperature can accelerate the decomposition of limestone. However, when the calcination temperature is higher than 1100 ° C, over-burning is liable to occur, the lime crystal grains are rapidly increased, the lime activity is deteriorated, the digestion time is increased, and the product quality is lowered. Therefore, the calcination temperature should be controlled at about 1050 ° C in actual production.

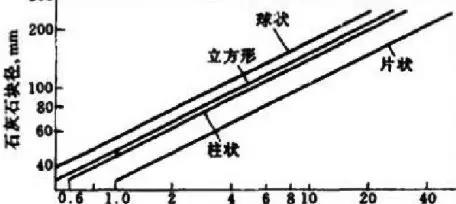

2. Granularity of Limestone The calcination speed of limestone depends on the particle size of limestone. The larger the particle size, the slower the calcination speed. Calcium carbonate in limestone is decomposed layer by layer from the surface to the inside. The thermal conductivity of lime is smaller than that of limestone. The thicker the limestone layer is, the worse the thermal conductivity is, and the longer the heat transfer time is; moreover, the more difficult the CO2 decomposed from limestone is to escape, which leads to the increase of CaO crystals and the decrease of decomposition speed due to the high temperature of lime. Therefore, the decomposition time of large size limestone is longer than that of small size limestone, and calcination is more difficult.

In addition, the uniformity of limestone particle size affects the calcination quality of limestone. If the size of limestone varies greatly, calcination according to large particle size will lead to over-burning of small particle size; calcination according to small particle size will lead to over-burning of large particle size; calcination according to medium particle size may lead to both over-burning and raw burning. In addition, the particle shape of limestone has an effect on calcination. Generally speaking, flake and column are not as good as spherical and cubic ones. Therefore, in the pretreatment of limestone, the particle size is best controlled at 75-150 mm, and the shape is close to spherical or cubic.

Relationship between limestone calcination time and particle size

The relationship between calcination time and particle size of limestone

The relationship between calcination time and particle size of limestone

3. Fuel Particle Size and Ratio The production of solid fuel in lime kiln usually uses coke and anthracite as fuel. The lump size of fuel must be compatible with the lump size of limestone, and the decline speed of fuel in kiln must be compatible with its combustion speed. If the particle size is too small, the temperature of preheating zone will rise, the heat of calcination layer will decrease, and the amount of lime will increase; if the particle size is too large, the fuel will not be able to burn completely in the calcination zone, so that the calcination zone will move downward, which is prone to lime overburning. In the process of limestone combustion, the proportion of fuel is the key factor affecting the calcination and decomposition of limestone. Low temperature, inadequate calcination and serious lime burning can not meet the requirements; conversely, excessive ratio can easily cause nodulation. Therefore, the combustion ratio should be appropriate and the operation measurement should be accurate. In actual production, the proportioning size should be adjusted in time and reasonably according to the changes of limestone particle size, fuel particle size, water content, kiln shutdown time, lime quality and output. Usually, the proportioning of anthracite is 2% higher than that of coke.

4. Air supply In general, the control of the amount of air is expressed by the pressure, that is, the supply air pressure. In the case of a suitable fuel ratio, the magnitude of the wind pressure will affect the up- or down-shift of the calcination zone in the lime kiln, and at the same time affect the change of the kiln gas during the calcination process. The main components of the kiln gas are: CO2, CO, O2, which should be controlled by φ(CO2)=40~42%, φ(CO)<0.4, φ(O2)≤1.0. When the CO2 content is lower than 35%, the raw calcination of the produced lime increases; when the CO content is high, the combustion of the fuel is incomplete, and it is also a feature of nodulation in the kiln; when the O2 concentration is too high, If the supply air volume is too large, it will increase the lime burn rate and heat loss, which is not conducive to calcination.

5. Kiln Loading Method The loading methods of lime kiln include mixed loading and layered loading. The mixing method can make the mixture of limestone and fuel more uniform, which is suitable for shaft kilns with small proportion and few primary fuels. The stratification method is convenient to adjust the distribution of fuel in the kiln cross section and suitable for shaft kilns with large proportion.