As a kind of pure natural stone, its main chemical composition is silica, followed by a small amount of iron oxide and trace elements and compounds such as manganese, copper, aluminum, magnesium and so on. They have different pigments, such as red for iron, blue for copper, purple for manganese, yellow translucent for silica colloidal pulp, emerald containing green minerals and so on; due to the different types and contents of these pigment ions dissolved into silica hydrothermal solution, they present a variety of colors, such as black, white, yellow, red, dark green Green and gray.

However, the cost of natural sand mining is gradually increasing. After years of continuous mining, natural sand resources are shrinking sharply. Moreover, national environmental protection policies have become more and more stringent, and many small sand factories have closed. As a result, the cost of natural sand is getting higher and higher, so its profit is getting lower and lower, and the market is getting smaller and smaller. In recent years, the market demand for machine-made sand has expanded, especially the huge demand in the construction market, which has promoted the rapid development of the sand and gravel market, and machine-made sand has gradually become one of the important sources of construction materials.

With the rapid development of real estate, the demand for construction sand is relatively large, and the quality requirements are limited. In some large-scale projects, the quality of sand and stone directly affects the quality of these projects. Therefore, in some cobble rich areas, the gravel sand machine production line can be used for processing. In addition to the advantages of less cost investment and quick income, its hard quality, bright and simple color, compression and wear resistance characteristics are also recognized by the industry, and become a widely used sand making machine equipment manufacturer. Furthermore, the pebble is an ideal green building material to meet the growing environmental requirements.

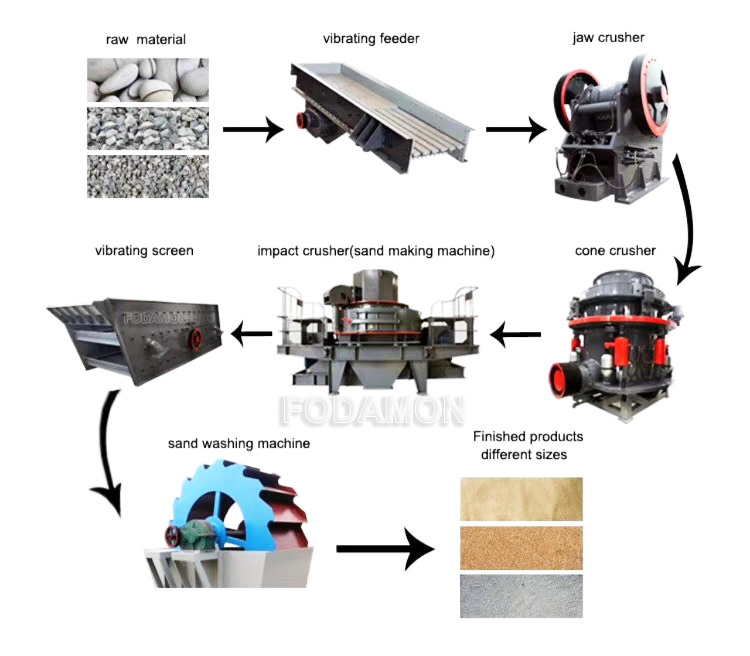

Here, Fodamon engineer recommends the sand preparation scheme for river pebbles. Jaw crusher is used for coarse crushing, hydraulic cone crusher for medium crushing and three-stage crushing scheme for sand making machine. The three-stage crushing scheme of jaw crusher + cone crusher + sand making machine: jaw crushing is the primary crushing of river pebbles, that is, coarse crushing. The hydraulic cone breaking is a layer crushing. The sand making machine adopts the principle of stone striking and stone striking iron crushing. The wear-resistant parts have a long cycle and the equipment maintenance time is short. The service life of the equipment is prolonged and the high output is guaranteed. Sand making machine has three functions: crushing, sand making and shaping, which is often used in the final process of crushing sand production line. It can produce 70-490 tons of sand and 150-580 tons of shaping per hour. It is suitable for limestone, pebble, granite, ore tailings, etc.