Mobile Crusher

Applied Materials:

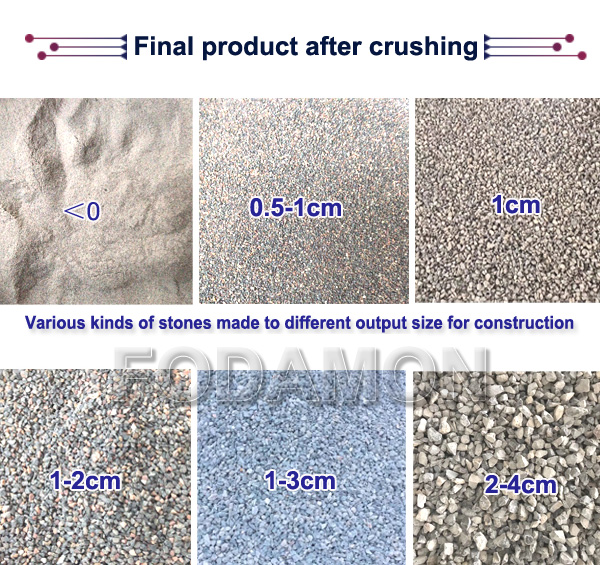

Construction waste, basalt, granite, fly ash, cement clinker, river pebbles, limestone, iron ore, bauxite, quartz sand, coal gangue, etc.

Applications:

Metallurgical, chemical, building materials, electricity, transportation and other industrial sectors.

If you want to learn more about our mobile crushing plant, Leave a Message!

Introduction of Mobile Crusher

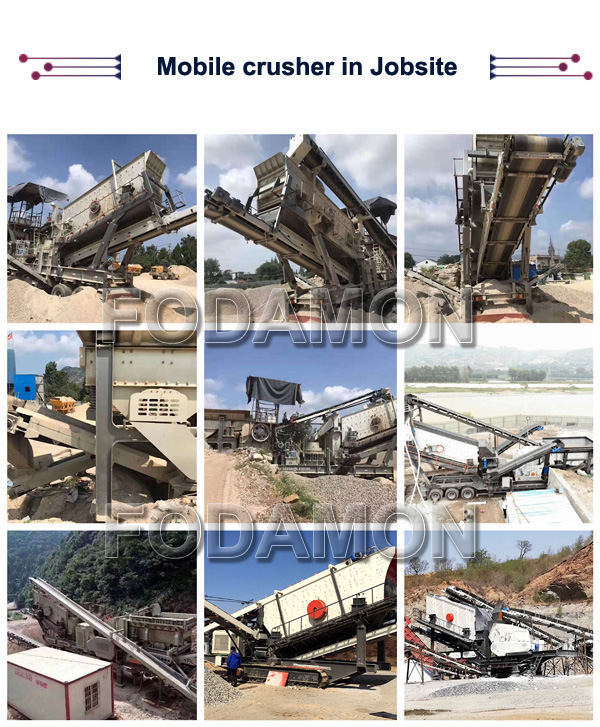

Mobile Crusher is a kind of mobile crusher which integrates crushing, screening and feeding operation. It is widely used to process pebble, basalt, granite, limestone, quartz, construction waste, concrete, gold ore, iron ore, coal and other stone, ore and other minerals.

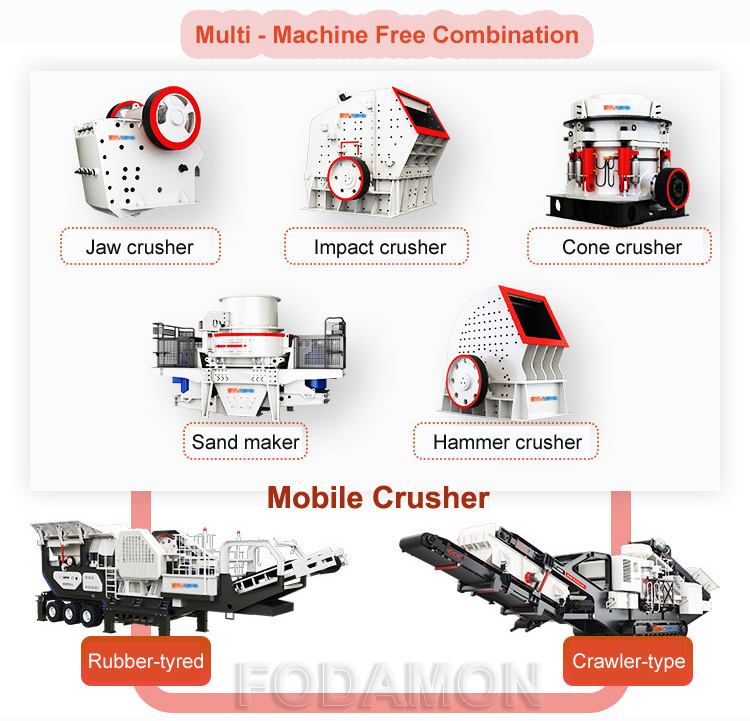

According to the different crushing materials, we have the existing production, Mobile Jaw Crusher, Mobile Sand Making Machine, Mobile Cone Crusher, Mobile Impact Crusher, Mobile Hammer Crusher, Mobile Vibrating screen, etc. Depending on the driving method, we have Rubber-Tyred Mobile Crushing Stations and Crawler-Type Mobile Crushing Stations. Tailor-made solutions for you.

If you want to learn more about our mobile crushing plant, Leave a Message!

Working Principle of Mobile Crusher

Working Principle of Mobile Crusher

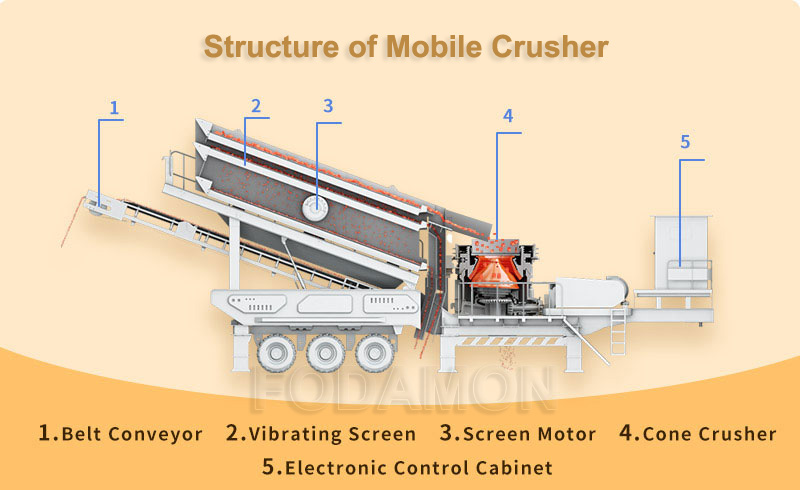

Compared with the ordinary crusher, the mobile crusher station has the advantages of convenient movement, small floor area, direct site selection, and can be put into production when it is placed on the site. Another important feature is that the ordinary crusher transfers the raw materials to the crushing chamber of the crusher, between the feeder and the crusher through the belt conveyor placed on the ore surface, while the mobile crusher station The raw material feeder of crusher in the crushing station is close to each other, and the intermediate cross does not need the transmission of conveyor. The raw material of ore surface is directly transported to the feeding port of crusher by shovel, and the raw material will be injected into the crusher at a fixed speed, which not only reduces the unnecessary process, but also greatly reduces the unnecessary trouble in the speed and cost. Each crushing device in the crushing station Prepare to work back and forth until all raw materials are broken.

If you want to learn more about our mobile crushing plant, Leave a Message!

If you want to learn more about our mobile crushing plant, Leave a Message!

Technical Data

|

SMC Jaw crusher |

SMC600 |

SMC750 |

SMC900 |

SMC1060 |

SMC1200 |

SMC1300PEX |

|

Transport dimension |

||||||

|

Length (mm) |

8600 |

9600 |

11097 |

13300 |

15800 |

9460 |

|

Width (mm) |

2520 |

2520 |

3759 |

2900 |

2900 |

2743 |

|

Height (mm) |

3770 |

3500 |

3500 |

4440 |

4500 |

3988 |

|

Weight (Kg) |

15240 |

22000 |

32270 |

57880 |

98000 |

25220 |

|

Axle load(kg) |

10121 |

14500 |

21380 |

38430 |

64000 |

14730 |

|

Traction pin load(kg) |

5118 |

7500 |

10890 |

19450 |

34000 |

10490 |

|

Jaw crusher |

||||||

|

Model |

PE400X600 |

PE500X750 |

PE600X900 |

PE750X1060 |

PE900X1200 |

PEX300X1300 |

|

Inlet size (mm) |

400X600 |

500X750 |

600X900 |

750X1060 |

900X1200 |

300X1300 |

|

Adjustment range of discharge port (mm) |

40-100 |

50-100 |

65-180 |

80-180 |

95-225 |

20-90 |

|

Capacity (m³/h) |

10-35 |

25-60 |

30-85 |

70-150 |

100-240 |

10-65 |

|

Vibrating feeder |

||||||

|

Hopper volume(m³) |

3 |

4 |

7 |

10 |

10 |

3 |

|

Width of Hopper(mm) |

2200 |

2500 |

3000 |

3000 |

3000 |

2200 |

|

Model |

GZT0724 |

GZT0724 |

GZT0932Y |

ZSW490X110 |

ZSW600X130 |

GZT0724 |

|

Belt conveyor |

||||||

|

Model |

B650X6 |

B800X7 |

B1000X8 |

B1000X11 |

B1200X13 |

B1000X7 |

Note: This is just reference. Please contact us to get suitable solution and competitive price.