VSI Sand Making Machine

Applied Materials:

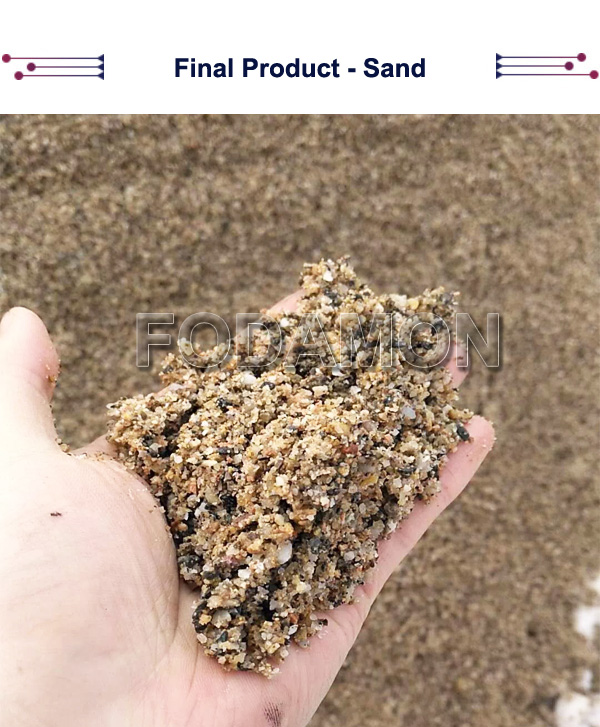

River pebble, granite, Xuan Wuyan, iron ore, limestone, calcite, quartzite, diabase and so on.

Applications:

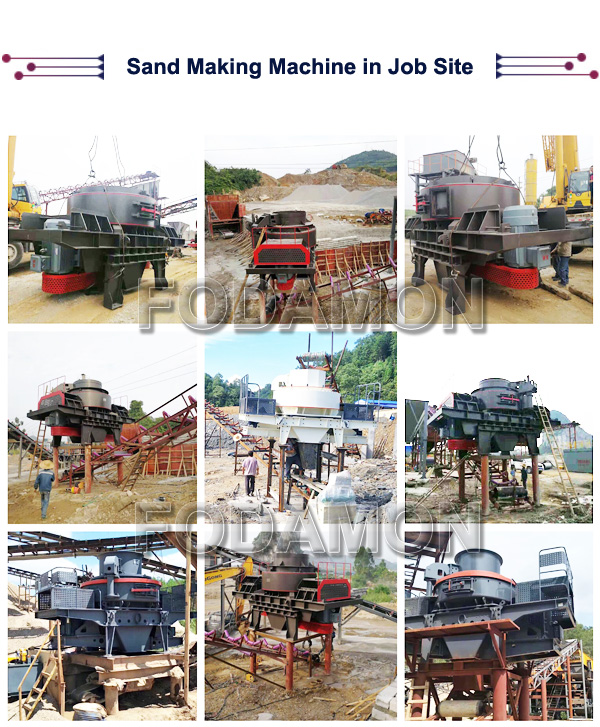

Sand and gravel yard, concrete sand making, dry powder mortar, machine-made sand, power plant desulphurization, quartz sand, etc.

If you want to learn more about our crushing equipment, Leave a Message!

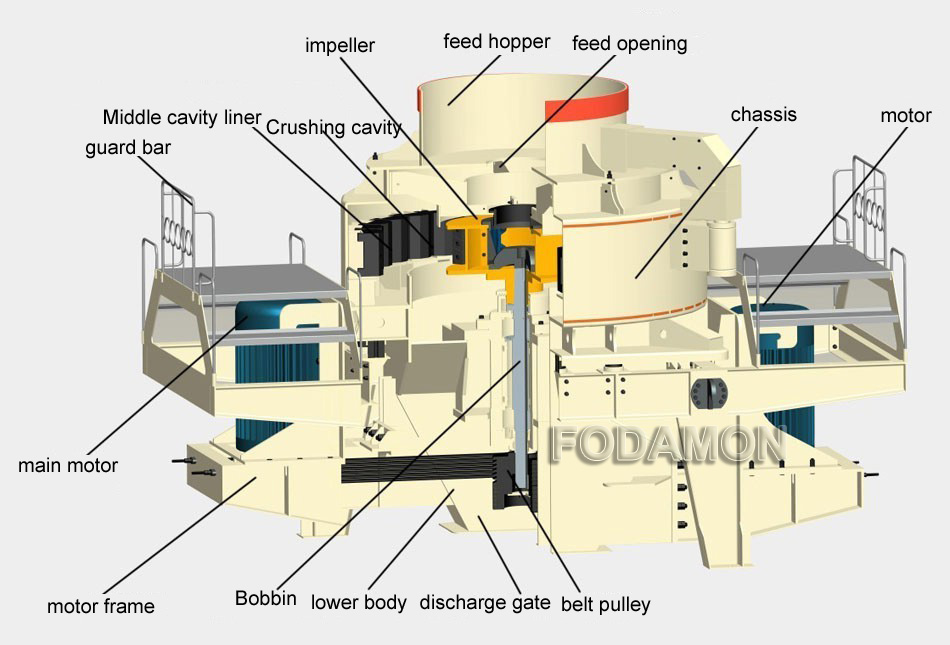

VSI Sand Making Machine Introduction

VSI sand making machine is a model of perfect combination of fine crushing and mechanical manufacturing. Its unique rotor structure design, wear-resistant material technology, crushing speed optimization and hydraulic design can provide high quality sand and gravel for expressway, high speed railway, high rise building, municipal construction, hydropower dam construction, and coagulant soil mixing station. It is the first choice in the field of artificial sand making and stone dressing.

Advantages of Fodamon VSI Sand Making Machine

1. Quality assurance, high efficiency and low consumption. High quality materials and advanced technology improve the internal quality and appearance quality of the equipment and ensure low failure rate. Reasonable design of impact angle of crushing chamber material reduces wear and use cost, and increases output by 30%.

2. One machine is multipurpose, and the grain type is excellent. Unique material crushing structure, with a variety of crushing cavity type, the realization of the “stone beating stone” and “stone iron” free conversion, making the finished product excellent, reasonable gradation, fine modulus adjustable, suitable for artificial sand, stone shaping and other fields.

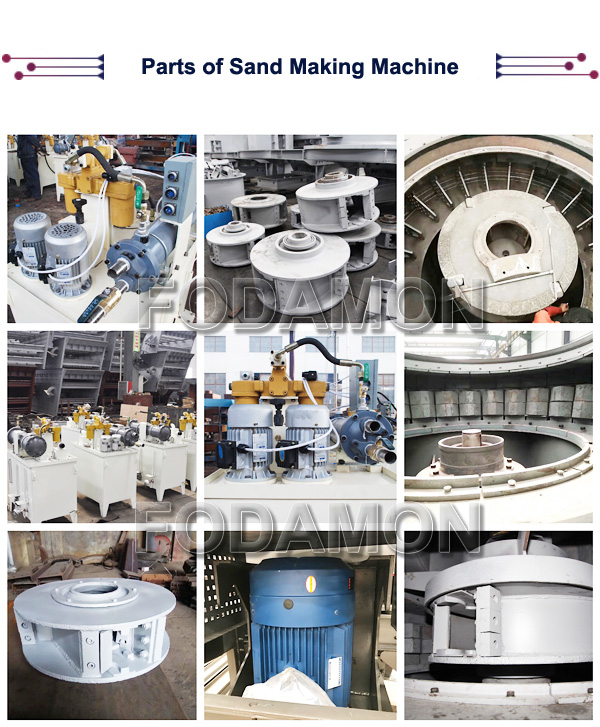

3. Unique design, easy to maintain. The hydraulic opening device is easy to repair and maintain, and saves time and effort. Over vibration display and alarm device, automatic detection, safe and reliable. The double oil pump complements oil supply at the thin oil lubrication station to ensure that the bearing lubrication is always in good condition and the service life of the equipment is prolonged

4. The self circulation system is beneficial to environmental protection. The unique air self circulation system greatly reduces the exhaust air volume, less dust, small noise, environmental protection, and can configure a variety of specifications of the dust removal equipment, and increase environmental protection.

Working Principle

Working Principle

Full center feed: the material falls into the feeder of the sand making machine and enters the high-speed rotating wheel through the central feed hole, which is speeded up rapidly in the swing wheel, and its acceleration can reach a number of times of gravity acceleration, and then it is thrown out from the swing wheel at high speed. First, it collide with another part of the free falling material after the rebound, and then hits the object together. The lining layer (stone beating stone) or the counterattack block (stone hitting iron) is rebounded to the top of the swirl chamber, and changes its movement direction, deflects the downward movement, and forms a continuous material curtain with the material emitted from the impeller flow path. In this way, a piece of material is subjected to two times to multiple chance impact, friction and grinding crushing, and the broken material is discharged from the lower discharge port.

The center feed is accompanied by a ring falling feed: the material falls into the feeder of the sand making machine and is divided into two pieces of material by the blanking plate, one of which enters the high speed rotating wheel, and the other falls from the round plate. The material entering the swing wheel is speeded up rapidly in the swing wheel, and its acceleration can reach dozens of times of gravity acceleration, and then it is thrown out of the swing wheel at high speed. First, it is shattered with the other part of the free falling body around the feeder, and then it is impacted on the swirl swirl lining layer together, and the material is rebounded and slanted upward. At the top of the vortex chamber, it changes its motion direction, deflects downward movement, and forms a continuous material curtain with the material emitted from the impeller channel. In this way, a piece of material is subjected to two times to multiple chance impact, friction and grinding crushing, and the broken material is discharged from the lower discharge port.

If you want to learn more about our crushing equipment, Leave a Message!

If you want to learn more about our crushing equipment, Leave a Message!

Technical Data of VSI Sand Making Machine

|

Model |

VSI-7611 |

VSI-8518 |

VSI-9526 |

VSI-1140 |

VSI-1145 |

VSI-1150 |

|

|

Capacity (t/h) |

Center and Ring |

120-180 |

200-260 |

300-380 |

450-520 |

500-610 |

520-650 |

|

Center feeding |

60-90 |

100-130 |

150-190 |

225-260 |

245-355 |

255-365 |

|

|

Max. Feeding Size |

Soft material |

35 |

40 |

45 |

50 |

50 |

50 |

|

Hard material |

30 |

35 |

40 |

40 |

45 |

45 |

|

|

Rotation speed(r/min) |

1700-1890 |

1520-1690 |

1360-1510 |

1180-1310 |

1150-1300 |

1150-1300 |

|

|

Power for double motor(kw) |

4P 110 kW |

4P 180 kW |

4P 264 kW |

4P 400 kW |

4P 400 kW |

4P 500 kW |

|

|

Overall Dimension (L×W×H)(mm) |

3700x2150x2100 |

4140x2280x2425 |

4560x2447x2778 |

5100x2700x3300 |

5500x2700x3300 |

5500x2700x3300 |

|

|

Power Supply |

380V 50HZ |

||||||

|

Lubrication hydraulic |

Power for double oil pump |

2×0.31 kW |

|||||

|

Safety |

To make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cools; start the motor by heating it in winter. |

||||||

|

Overall dimension |

820×520×1270 |

||||||

|

Power for oil box heater |

2 kW |

||||||

Note: This is just reference. Please contact us to get price and details.