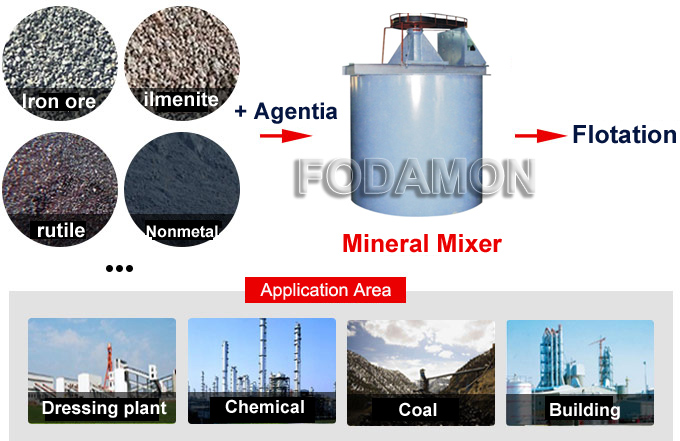

Mineral Mixer

Applied Materials:

Copper ore, pyrrhotite, hematite, limonite, molybdenum ore, gold ore, iron ore, etc.

Applications:

Production industries such as cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics.

If you want to learn more about our beneficiation equipment, Leave a Message!

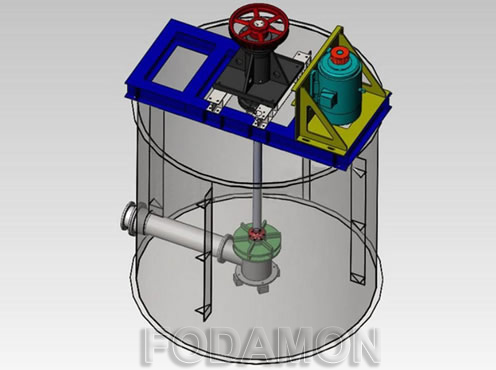

Mineral mixer (Conditioning tank) is mainly used to mix slurry before flotation in the beneficiation process. It can mix drug and slurry completely. It is suitable to mix slurry with density smaller than 30 % (weight ratio) and size smaller than 1mm. V-belt of motor drives impeller to mix drug and slurry completely. This machine can increase reaction time and strengthen reaction quality of the drug. The mixing bucket includes forced mixing bucket, single horizontal axis mixing bucket, double horizontal axis mixing bucket and so on.

Working principle

Working principle

The mixing bucket is composed of motor, impeller, stator, bearing and other components. The mixing operation is carried out by using the flat bottom drum radiation circulation spiral impeller mechanical mixing method. When the mixing tank is working, the motor pulls the triangle belt drive device to drive the impeller to rotate. Under the constant speed mixing of the impeller, the slurry and the agent can fully mix with each other, increase the reaction time of the agent to the slurry, strengthen the reaction quality of the drug, so that the material can be fully stirred and mixed, and make necessary preparation for the next stage of the flotation machine production.

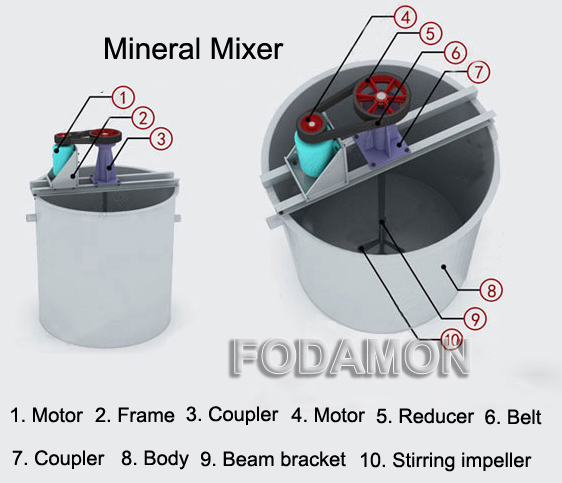

Structure of Mineral Mixing Bucket

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Mineral mixer technical parameter

|

Category |

Model |

Dimensions |

Effective |

Rotate |

Power |

Dimensions |

Weight |

|

|

Diameter |

Height |

|||||||

|

Agitating tank |

XB-10×10 |

1000 |

1000 |

0.58 |

390 |

1.5 |

1130x1130x1521 |

1050 |

|

XB-12×12 |

1200 |

1200 |

1.18 |

390 |

2.2 |

1130x1330x1721 |

1160 |

|

|

XB-15×15 |

1500 |

1500 |

2.2 |

280 |

3.0 |

1750x1640x2190 |

1270 |

|

|

XB-20×20 |

2000 |

2000 |

5.6 |

210 |

5.5 |

2380x2160x2850 |

1700 |

|

|

XB-25×25 |

2500 |

2500 |

11.2 |

190 |

7.5 |

2990x2720x3540 |

3500 |

|

|

XB-30×30 |

3000 |

3000 |

19 |

140 |

18.5 |

4030x3270x3010 |

5200 |

|

|

XB-35×35 |

3500 |

3500 |

29 |

230 |

30 |

3920x3740x4970 |

6630 |

|

|

XB-40×40 |

4000 |

4000 |

45 |

210 |

37 |

4520x4320x5570 |

7830 |

|

|

Lifting type |

XBT-10×15 |

1000 |

1500 |

1 |

510 |

2.2 |

1130x1130x2070 |

1250 |

|

XBT-15×20 |

1500 |

2000 |

2.9 |

400 |

4 |

1636x1768x2785 |

1677 |

|

|

XBT-20×20 |

2000 |

2000 |

5.6 |

312 |

11 |

2180x2220x3015 |

3100 |

|

|

High-efficiency |

XF-20×20 |

2000 |

2000 |

7.07 |

82.5 |

1.5 |

2032x2032x3595 |

2400 |

|

XF-25×30 |

2500 |

3000 |

13.5 |

57.6 |

2.2 |

2532x2532x4152 |

3670 |

|

|

XF-30×30 |

3000 |

3000 |

22.97 |

50.0 |

2.2 |

3180x3180x4673 |

5340 |

|

|

XF-35×40 |

3500 |

4000 |

35.6 |

41.0 |

4.0 |

3685x3685x5314 |

7140 |

|

|

XF-40×45 |

4000 |

4500 |

52.78 |

33.5 |

4.0 |

4185x4185x5814 |

9300 |

|

|

XF-45×50 |

4500 |

5000 |

74.75 |

33.5 |

5.5 |

4685x4685x6466 |

10500 |

|

|

XF-50×56 |

5000 |

5600 |

102.1 |

30.6 |

5.5 |

5185x5185x6975 |

12300 |

|

|

XF-55×60 |

5500 |

6000 |

135.4 |

24.4 |

7.5 |

5670x5670x7569 |

13500 |

|

Note:This is just reference. Please contact us to get suitable solution and competitive price.