The 500tpd gold ore beneficiation equipment project in Shaanxi is one of most challenging project in the 19-year plant installation and general contracting project of our factory. The challenge is not because of the cutting-edge difficulties in equipment installation technology, but in the hot summer days. The project has a short construction period and an average temperature of 35 ° C. However, it can still be controlled with high precision and high intensity. The connection and measurement of each detail ensure that each process is accurate to the smallest error with the design manuscript, reducing the minimum cost and equipment load in the post-selection production, and satisfying the customer. And rest assured, this is the heart of Fodamon, and it is the vision of mining companies.

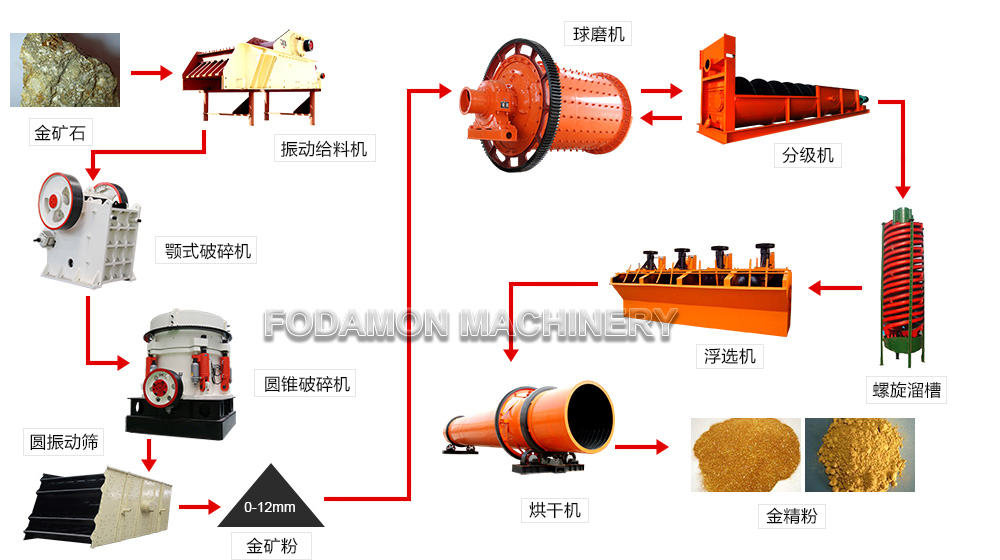

The project is the equipment installation general contracting project of the gold mine flotation plant, and its beneficiation process is:

Two-stage closed-circuit crushing system, grinding system, flotation system, and filter press system. In the whole flotation plant project, our company’s project technology department is mainly responsible for: the installation and construction of the equipment required for the project, and the commissioning of the equipment.

In the installation process of the belt conveyor, in order to prevent the technical failure of the belt deviation during the post-production operation, from the initial installation, the technician strictly controls the precision dimension of the design original and the standard specifications of the equipment to reduce the production operation. The most common hazard in the process, and the basis of the most likely neglected production factors. A big problem that may seem to be caused by a small problem.

Fodamon, with professional technology to practice, speak with the Seiko project, always insist on customer satisfaction and peace of mind, from the source to pay attention to the probability of this possibility.

In the installation of the flotation machine plant, although the flotation machine itself has good stability, it must ensure the level of overflow weir. During the installation process of the flotation machine, special attention should be paid to the deviation from the longitudinal, transverse and center, the limit deviation of the elevation, the welding deviation when the grooves are linked, the positioning of the trough, the installation of the pad, the platform or the embedded parts, the vertical axis and the transmission. Assembly, foam scraper installation, etc.

From the drawing information data to the actual field equipment operation, each place reflects the power of high-precision technical team, and each time it can show the technical specialization and scientific management degree of Fodamon.

When the sun is shining and the sweat is raining, the hard environment obviously cannot stop the prospect of the mineral source. There are still many difficulties and confusions in the pursuit of green mine roads, but Fodamon always believes: insist on good mechanical production, and constantly improve and upgrade solutions. We always believe that we must adhere to our customers’ needs and adhere to our beliefs. , choose a good faith agreement, The rest is left to witness. Fodamon people are on the road.