Briquette Machine

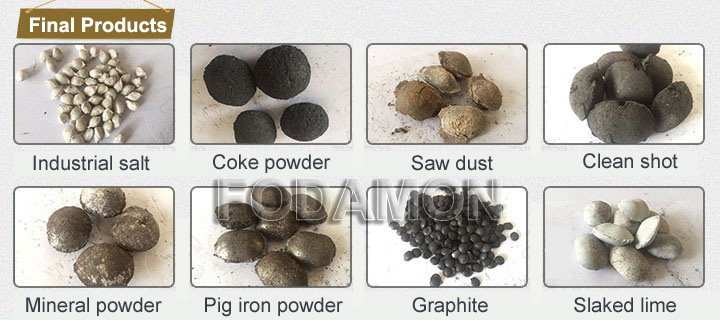

Applied Materials:

Dust, mud, oxide scale, steel slag, iron concentrate, aluminum ash, silicon manganese ore powder, coal powder, coke powder and so on.

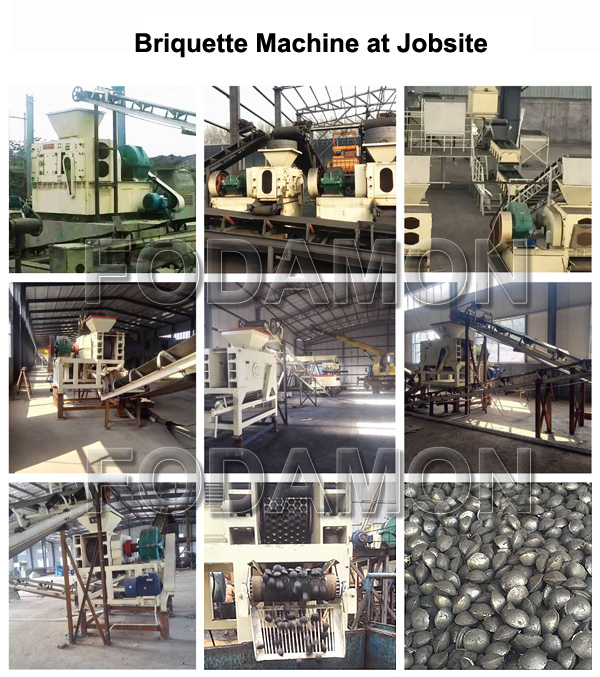

Applications:

Industrial gas making, boiler type, cold pressing focus, ignition briquette, civil briquette, civil metallurgy, refractories, medicine, etc.

If you want to learn more about our briquette machine, Leave a Message!

Introduction of Briquette Machine

Introduction of Briquette Machine

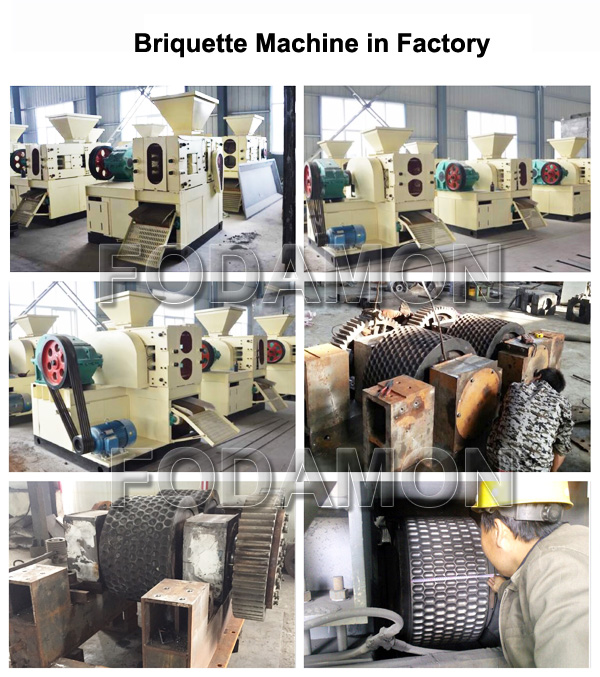

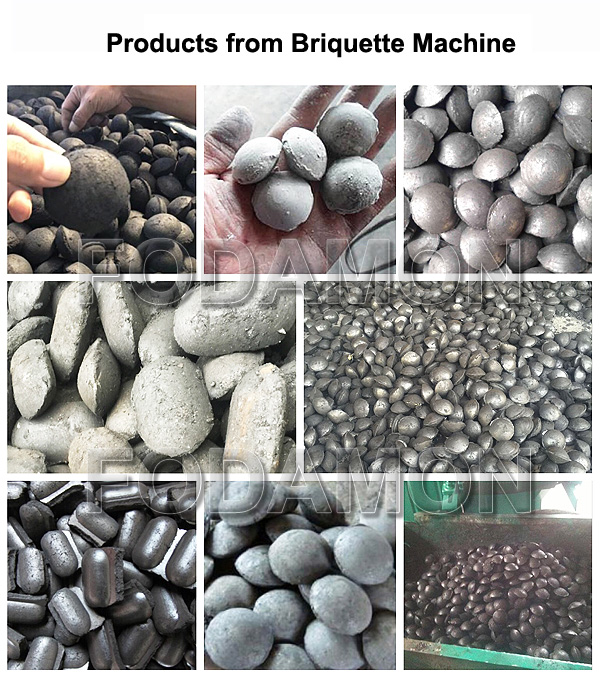

Briquette machine is mainly used to press the powder materials which are difficult to form. It is characterized by large forming pressure, adjustable rotation of the main machine and equipped with screw feeding device. Briquette machine can be used to press coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder and other powder, powder, waste material, waste residue, widely used in refractory, power plant, metallurgy, chemical industry, energy, transportation, heating and other industries. After being made by ball press, the materials are energy-saving It is convenient for transportation, improves the utilization rate of waste materials, and has good economic and social benefits.

Working Principle

Working Principle

The main engine is powered by the electromagnetic speed regulating motor and transmitted to the driving shaft through the belt pulley, the cylindrical gear reducer and the bar pin coupling. The driving shaft and the passive shaft are operated synchronously by open gear. A hydraulic device is arranged behind the passive bearing seat. The screw feeding device is driven by the electromagnetic speed regulating motor, and rotates through the belt pulley and worm reducer to force the pressed material into the main feeding port.

If you want to learn more about our briquette machine, Leave a Message!

If you want to learn more about our briquette machine, Leave a Message!

Technical Data

|

Model |

Roller size |

Speed of main shaft (r/min) |

Power (kw) |

Capacity (t/h) |

Overall size |

|

FDXM-290 |

290×200 |

12-15 |

5.5-7.5 |

1-3 |

1.6×1.2×1.4 |

|

FDXM-360 |

360×250 |

12-15 |

7.5-11 |

3-5 |

2.1×1.3×1.76 |

|

FDXM-430 |

430×250 |

12-15 |

15-18.5 |

4-7 |

2.3×1.53×1.9 |

|

FDXM-500 |

500×300 |

12-15 |

22-30 |

5-10 |

2.6×1.75×2.1 |

|

FDXM-650 |

650×350 |

10-13 |

37-55 |

8-13 |

3.42x2x2.2 |

|

FDXM-750 |

750×380 |

10-13 |

45-75 |

12-17 |

3.7×2.55×2.6 |

|

FDXM-850 |

850×460 |

10-13 |

75-110 |

15-20 |

3.9×2.6×2.7 |

|

FDXM-1000 |

1000×530 |

10-13 |

110-132 |

20-30 |

4×2.8×2.8 |

Note: This is just reference. Please contact us to get price and details.