Spiral Classifier

Applied Materials:

Quartzite, gold ore, iron ore, copper ore, ore, pulp, fine mud, cement clinker, pyrrhotite, etc.

Applications:

Cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramics production industries.

If you want to learn more about our beneficiation equipment, Leave a Message!

The Spiral classifier is widely used in ore dressing plant and ball mill to form closed-circuit circulation and separate ore sand, or in gravity ore dressing plant to classify ore sand and fine mud, in metal ore dressing process to carry out particle size classification of ore pulp, and in ore washing operation to desliming, dehydration and other operations. The classifier has the advantages of simple structure, reliable operation and convenient operation. Spiral classifier is called classifier for short. There are four types of classifier: high weir single screw and double screw, submergence single screw and double screw.

The Spiral classifier is widely used in ore dressing plant and ball mill to form closed-circuit circulation and separate ore sand, or in gravity ore dressing plant to classify ore sand and fine mud, in metal ore dressing process to carry out particle size classification of ore pulp, and in ore washing operation to desliming, dehydration and other operations. The classifier has the advantages of simple structure, reliable operation and convenient operation. Spiral classifier is called classifier for short. There are four types of classifier: high weir single screw and double screw, submergence single screw and double screw.

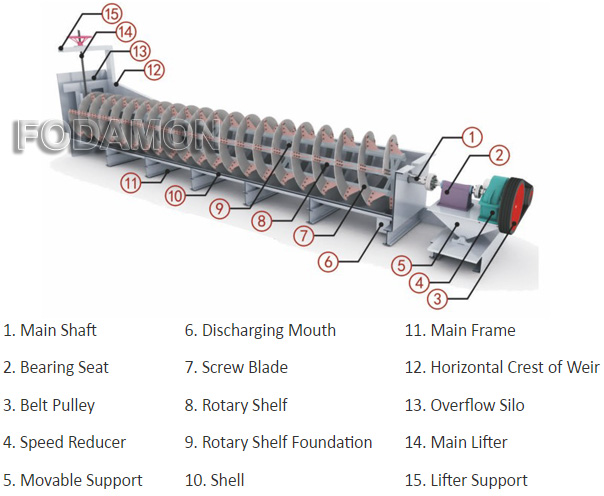

Structure of Spiral classifier

The classifier of our company is mainly composed of transmission device, screw body, tank body, lifting mechanism, lower support (bearing bush) and ore discharge valve. The classifier produced by our company adopts advanced technology research and development, featuring simple structure, reliable work, convenient operation, etc.

If you want to learn more about our beneficiation equipment, Leave a Message!

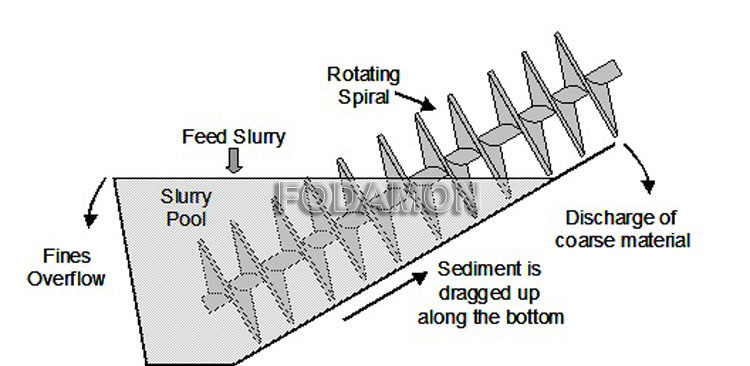

Working principle of Spiral classifier

Working principle of Spiral classifier

When the machine is working, the classifier is based on the principle of different solid particle size and specific gravity, so the settling speed in the liquid is different. Fine ore particles float in the water and overflow, and coarse ore particles sink at the bottom of the tank. A classification equipment that pushes the screw to the upper part to discharge for mechanical classification. It can grade the material and powder grinded out of the mill to filtration, and then screw the coarse material into the mill feed port by using the spiral slice spiral disc to discharge the filtered fine material from the overflow pipe. The base of the machine is made of channel steel and the body is welded with steel plate. The screw shaft’s water head, shaft head, adopt pig iron sleeve, wear-resistant and durable. The lifting device is divided into electric and manual.

Performance characteristics of Fodamon Classifier

1. The screw shaft’s inlet head and shaft head adopt pig iron sleeve, which is reliable in operation and has good washing effect.

2. Fine grading granularity can meet different needs of customers, with high sand return rate.

3. The base is made of channel steel and the body is welded with steel plate, with good quality and high wear resistance.

4. The classifier adopts tile lining, with very low maintenance rate and high durability of vulnerable parts.

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical parameters of spiral classifier

|

Model |

Spiral diameter(mm) |

length(mm) |

Rotary speed(r/min) |

Capacity(t/d) |

Power(kw ≤) |

Overall size(mm≤le;) |

Weight(t) |

||||

|

Sand return |

Overflow |

Driving |

Lifting |

Length |

Width |

Height |

≤ |

||||

|

FG-3 |

300 |

3000 |

12-30 |

80-150 |

20 |

1.1 |

—- |

3850 |

490 |

1140 |

0.7 |

|

FG-5 |

500 |

4500 |

8-12.5 |

135-210 |

32 |

1.1 |

—- |

5430 |

680 |

1480 |

1.9 |

|

FG-7 |

750 |

5500 |

6-10 |

340-570 |

65 |

3 |

—- |

6720 |

980 |

1820 |

3.1 |

|

FG-10 |

1000 |

6500 |

5-8 |

675-1080 |

110 |

5.5 |

—- |

7590 |

1240 |

2380 |

4.9 |

|

FC-10 |

8400 |

675-1080 |

85 |

7.5 |

—- |

9600 |

1240 |

2680 |

6.2 |

||

|

FG-12 |

1200 |

6500 |

4-6 |

1170-1870 |

155 |

7.5 |

2.2 |

8180 |

1570 |

3110 |

8.5 |

|

FC-12 |

8400 |

1170-1870 |

120 |

7.5 |

2.2 |

10370 |

1540 |

3920 |

11.0 |

||

|

2FG-12 |

6500 |

2340-3740 |

310 |

15 |

4.4 |

8230 |

2790 |

3110 |

15.8 |

||

|

2FC-12 |

8400 |

2340-3740 |

240 |

15 |

4.4 |

10370 |

2790 |

3920 |

17.6 |

||

|

FG-15 |

1500 |

8300 |

4-6 |

1830-2740 |

235 |

7.5 |

2.2 |

10410 |

1880 |

4080 |

12.5 |

|

FC-15 |

10500 |

1830-2740 |

185 |

7.5 |

2.2 |

12670 |

1820 |

4890 |

16.8 |

||

|

2FG-15 |

8300 |

2280-5480 |

470 |

15 |

4.4 |

10410 |

3390 |

4080 |

22.1 |

||

|

2FC-15 |

10500 |

2280-5480 |

370 |

15 |

4.4 |

12670 |

3370 |

4890 |

30.7 |

||

|

FG-20 |

2000 |

8400 |

3.6-5.5 |

3290-5940 |

400 |

11-15 |

3 |

10790 |

2530 |

4490 |

20.5 |

|

FC-20 |

12900 |

3210-5940 |

320 |

11-15 |

3 |

15610 |

2530 |

5340 |

28.5 |

||

|

2FG-20 |

8400 |

7780-11880 |

800 |

22-30 |

6 |

11000 |

4600 |

4490 |

35.5 |

||

|

2FC-20 |

12900 |

7780-11880 |

640 |

22-30 |

6 |

15760 |

4600 |

5640 |

48.7 |

||

|

FG-24 |

2400 |

9130 |

3.67 |

6800 |

580 |

15 |

3 |

11650 |

2910 |

4970 |

26.8 |

|

FC-24 |

14130 |

6800 |

490 |

18.5 |

4 |

16580 |

2930 |

7190 |

41.0 |

||

|

2FG-24 |

9130 |

13600 |

1160 |

30 |

6 |

12710 |

5430 |

5690 |

45.8 |

||

|

2FC-24 |

14130 |

13700 |

910 |

37 |

8 |

17710 |

5430 |

8000 |

67.9 |

||

|

2FG-30 |

3000 |

12500 |

3.2 |

23300 |

1785 |

40 |

8 |

16020 |

6640 |

6350 |

73.0 |

|

2FC-30 |

14300 |

23300 |

1410 |

—- |

—- |

17091 |

—- |

8680 |

84.8 |

||

Note:This is just reference. Please contact us to get suitable solution and competitive price.