Magnetic Separator

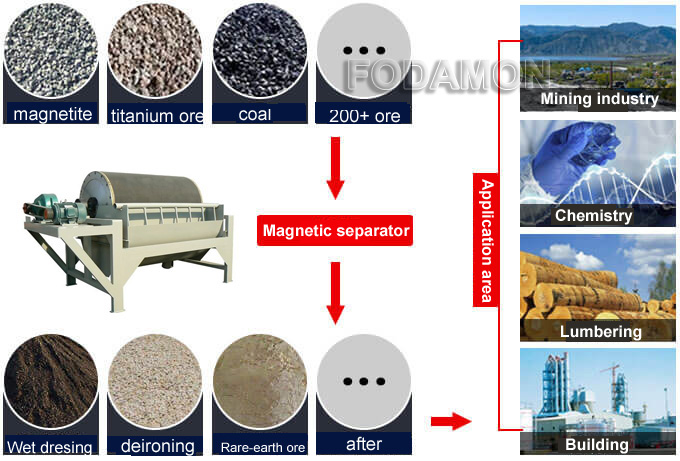

Applied Materials:

Iron ore, hematite, pyrrhotite, limonite, calcined ore, ilmenite, magnetite, copper ore, gold ore, coal, quartz and so on.

Applications:

Wet magnetic separation of magnetite, pyrrhotite, calcined ore, ilmenite and other materials with a particle size of 3 mm or less.

If you want to learn more about our beneficiation equipment, Leave a Message!

Magnetic separators are divided into dry magnetic separators and wet magnetic separators. According to the needs of users, we can provide various models such as forward flow, half reverse flow and reverse flow. This series of magnetic separators are suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm, and also for iron removal of coal, non-metallic ore, building materials and other materials. The magnetic separator can separate the different magnetic substances, which is one of the widely used and high universal machines in the industry. The magnetic system of our company’s magnetic separator is made of high-quality ferrite material or composite with rare earth magnetic steel, which has the advantages of simple structure, large processing capacity, convenient operation, easy maintenance, etc.

Application Scope

There are many minerals that can be separated by the magnetic separator, such as magnetite, limonite, hematite, manganese siderite, ilmenite, wolframite, manganese ore, manganese carbonate ore, manganese ore, manganese oxide ore, iron ore, kaolin, rare earth ore, etc., which can be separated by the magnetic separator.

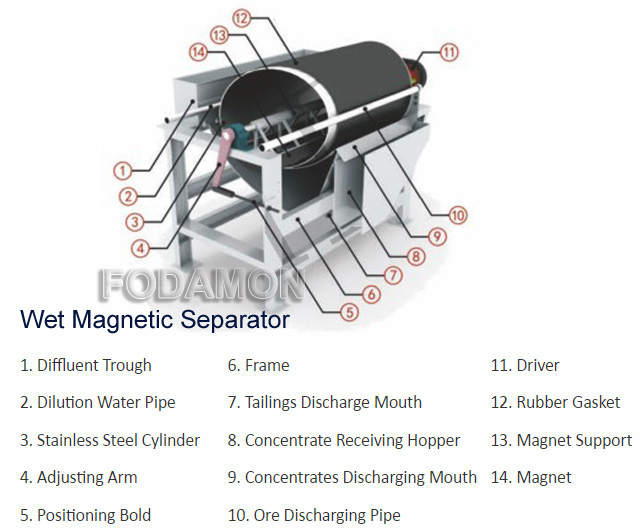

Structure of Magnetic separator

If you want to learn more about our beneficiation equipment, Leave a Message!

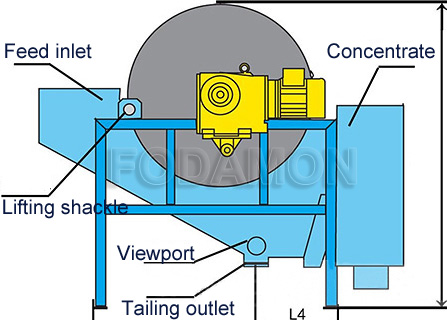

Working principle

Working principle

After the pulp flows into the tank through the ore feed tank, under the action of the water flow of the ore feed spout pipe, the ore particles enter the ore feed area of the tank in a loose state. Under the action of magnetic field, the magnetic ore particles gather to form “magnetic group” or “magnetic chain”. The “magnetic group” or “magnetic chain” moves to the magnetic pole under the action of magnetic force in the pulp and is adsorbed on the cylinder. Because the polarity of the magnetic pole is alternately arranged along the rotation direction of the cylinder, and it is fixed when working, “magnetic mass” or “magnetic chain” is rotating with the cylinder, the phenomenon of magnetic agitation occurs due to the alternation of the magnetic pole, the gangue and other non-magnetic minerals mixed in the “magnetic mass” or “magnetic chain” fall off during the turning, and finally are absorbed in the “magnetic mass” or “magnetic Lotus” on the cylinder surface. The concentrate is transferred to the weakest magnetic field at the edge of the magnetic system along with the cylinder, and is discharged into the concentrate tank under the action of flushing water from the ore discharge pipe. Nonmagnetic or weak magnetic minerals are left in the slurry and discharged out of the tank with the slurry.

Advantages of Fodamon high strength magnetic separator

Advantages of Fodamon high strength magnetic separator

1. According to the user’s needs, it can provide a variety of magnetic separation with different surface strengths, such as forward current, half reverse current and reverse current. The high strength magnetic separator has the advantages of simple structure, large processing capacity, convenient operation, easy maintenance, etc.

2. The semi countercurrent tank is suitable for the wet roughing and cleaning of the strong magnetic minerals with the particle size of 0.5-0mm, especially for the cleaning of the large minerals with the particle size of 0.15-0mm.

3. Countercurrent tank is suitable for wet roughing and sweeping of 0.6-mm strong magnetic minerals. Especially suitable for heavy medium recovery in coal washing plant.

4. The downflow tank is suitable for the roughing and cleaning of ore with particle size of 6-0mm.

5. Semi countercurrent tank and downstream tank can be used in series to improve concentrate grade.

6. The equipment has super high wear resistance and high temperature resistance, very reliable quality, super high output, and the magnetic separation efficiency is more than three times that of the ordinary magnetic separator.

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Magnetic separator Technical Data

|

Model |

Shell diameter |

Shell length |

Shell speed |

Feeding size |

Processing capacity |

Power |

|

CTB6012 |

600 |

1200 |

<35 |

2-0 |

10-20 |

1.5 |

|

CTB6018 |

600 |

1800 |

<35 |

2-0 |

15-30 |

2.2 |

|

CTB7518 |

750 |

1800 |

<35 |

2-0 |

20-45 |

2.2 |

|

CTB9018 |

900 |

1800 |

<35 |

3-0 |

40-60 |

3 |

|

CTB9021 |

900 |

2100 |

<35 |

3-0 |

45-60 |

3 |

|

CTB9024 |

900 |

2400 |

<28 |

3-0 |

45-70 |

4 |

|

CTB1018 |

1050 |

1800 |

<20 |

3-0 |

50-75 |

5.5 |

|

CTB1021 |

1050 |

2100 |

<20 |

3-0 |

50-100 |

5.5 |

|

CTB1024 |

1050 |

2400 |

<20 |

3-0 |

60-120 |

5.5 |

|

CTB1218 |

1200 |

1800 |

<18 |

3-0 |

80-140 |

5.5 |

|

CTB1224 |

1200 |

2400 |

<18 |

3-0 |

85-180 |

7.5 |

|

CTB1230 |

1200 |

3000 |

<18 |

3-0 |

100-180 |

7.5 |

|

CTB1530 |

1500 |

3000 |

<14 |

3-0 |

170-280 |

11 |

Belt Permanent Magnetic Separator Technical Data

|

Model |

Belt width adaptive (mm) |

Suspension height rated(mm) |

Magnetic intensity(mT) |

Material thickness(mm) |

Power(kw) |

Belt speed(m/s) |

Weight(kg) |

Overall size |

|

XFZ50 |

500 |

150 |

60 |

80 |

1.5 |

4.5 |

750 |

1900x735x935 |

|

XFZ65 |

650 |

200 |

70 |

150 |

2.2 |

4.5 |

1200 |

2165x780x1080 |

|

XFZ80 |

800 |

250 |

70 |

200 |

2.2 |

4.5 |

1400 |

2350x796x1280 |

|

XFZ100 |

1000 |

300 |

70 |

250 |

3.0 |

4.5 |

2120 |

2660x920x1550 |

|

XFZ120 |

1200 |

350 |

70 |

300 |

4.0 |

4.5 |

3350 |

2900x970x1720 |

|

XFZ140 |

1400 |

400 |

70 |

350 |

4.0 |

4.5 |

4450 |

3225x1050x1980 |

Note:This is just reference. Please contact us to get suitable solution and competitive price.