Disk Granulator

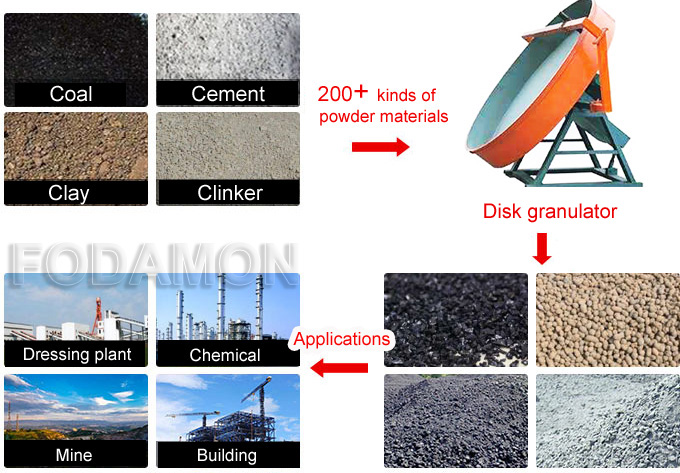

Applied Materials:

Quartzite, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, etc.

Applications:

Cement, silicate products, new building materials, refractory materials, fertilizer, black and non-ferrous metal beneficiation and glass ceramics.

If you want to learn more about our beneficiation equipment, Leave a Message!

Introduction of Disk Granulator

Introduction of Disk Granulator

Disc granulator is transformed from our factory based on advanced technology of similar equipment at home and abroad. The disc granulation plate lining with high strength glass steel has the advantages of uniform granulation, high granulating rate, smooth operation, durable equipment, long service life and so on. It is an ideal granulating equipment.

The whole circular arc structure is used to make the pellet round, and the granulation rate can reach more than 93. The granulation disc is provided with three discharging ports, which is convenient for intermittent production operations, greatly reduces labor intensity and improves labor efficiency. The reducer and motor are driven by flexible belt, starting smoothly, slowing down the impact force and improving the service life of the equipment. The bottom of the granulation tray is strengthened by multiple radiant steel plates, which is durable and never deformed. The design of the thickened, heavier and stronger base does not need to be fixed with anchor bolts, and operates smoothly.

Advantages of Fodamon Disk Granulator

Advantages of Fodamon Disk Granulator

1. The rate of ball formation is high.

2. The particle has a large round strength.

3. The operation is intuitionistic.

4. It is convenient to repair.

Working Principle

The method is pre added to the ball plate. Raw meal powder is evenly wetted in the double shaft mixer by atomizing water, forming a spherical core with uniform grain size, and then sent into the ball plate for ball formation. The moisture of the ball should be controlled from 12 to 14%. Most of the water should be added to the double shaft mixer, and only a small amount of additional water is added to the pellet. The additional water will be controlled between 0 and 3%. The dry powder granulation is directly added to the ball forming plate and sprinkled appropriate amount of water. The nucleus of the raw material enters the disc and is subjected to centrifugal force, friction and gravity, and moves along the parabola.

Because of the cohesiveness and plasticity of the material, the core is bonded and gradually grown up during the movement. As the angle of the ball plate, the height of the disc, the speed and the water, the ball of different particle size is rolling down the edge of the disc by different disengagement angles because of the different gravity. The ball in the process of continuous rolling process the water in the ball out of the surface, due to the adhesion of the material and the natural evaporation of the surface liquid film, so that the ball has a certain strength, and then with the rotation of the tilt disc from the edge of the disc out of the disc.

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical Data

|

Specification |

Rotation speed |

Production capacity |

Motor |

Adjustment range of obliquity |

Dimensions |

Total weight |

|

Φ2.2 |

14.25 |

4-8 |

7.5 |

35-55 |

2.8×2.75×2.58 |

3.2 |

|

Φ2.5 |

11.81 |

5-10 |

7.5 |

35-55 |

3.2×2.3×3 |

3.6 |

|

Φ2.8 |

11.21 |

12-16 |

7.5 |

35-55 |

3.4×2.6×3.1 |

4.1 |

|

Φ3.0 |

11.3 |

15-18 |

11 |

35-55 |

3.7×2.7×3.3 |

4.8 |

|

Φ3.2 |

9.6 |

15-20 |

11 |

35-55 |

3.9×2.7×3.4 |

5.6 |

|

Φ3.6 |

9.1 |

18-24 |

15 |

35-55 |

4.3×3.1×4.0 |

7.2 |

Note: This is just reference. Please contact us to get price and details.