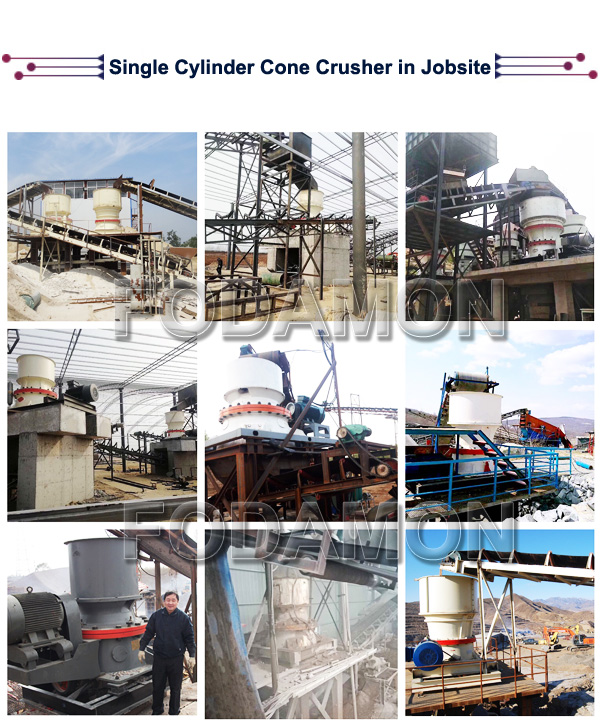

Single Cylinder Cone Crusher

Applied Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Applications:

Sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

If you want to learn more about our crushing equipment, Leave a Message!

Introduction of Single Cylinder Cone Crusher

Introduction of Single Cylinder Cone Crusher

The single cylinder hydraulic cone crusher is developed by the world’s advanced crushing technology. It integrates mechanical, hydraulic, electrical and intelligent control technologies. The new crusher structure, combined with the optimized laminating cavity type and all intelligent automatic control system, makes the G series single cylinder hydraulic cone crusher have unparalleled performance characteristics of the traditional cone crusher. It can be widely applied to medium crushing, fine crushing and ultra fine crushing. It is widely used in metallurgy, construction, cement, water conservancy, highways, railways, mineral processing and other fields, and has the functions of medium crushing, fine crushing and ultra fine crushing.

Know more about Fodamon Single Cylinder Cone Crusher

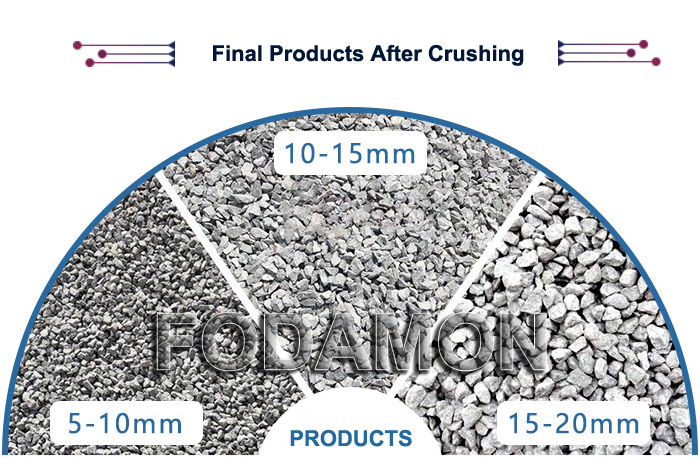

1. The hydraulic cone crusher adopts the unique crushing chamber and the principle of laminating crushing, which produces the crushing effect between the particles, thus the proportion of the cube in the finished product is obviously increased, the needle like stone is reduced, and the particle size is even more uniform.

2. Double insurance controlled hydraulic and lubrication system ensures overload protection and good bearing lubrication.

3. The production capacity is large and the crushing efficiency is high.

4. A variety of cavity combination, suitable for a variety of grain needs.

5. Long use time for vulnerable parts.

6. The structure is simple, easy to maintain and low operating cost.

7. The automatic control system uses the control mode of PLC+ touch screen to monitor the core parameters such as temperature, pressure and current in real time, and carries out automatic control to ensure the safe operation of the equipment.

Working Principle

When the single cylinder cone crusher works, the motor drives the small gear of the crusher, the small gear drives the big gear, the large gear component (large gear, big tooth wheel frame, eccentric steel sleeve) drives the eccentric sleeve components (eccentric cylinder sleeve, eccentric copper sleeve) and the spindle assembly (main shaft, inner cone and inner cone liner) as the center of theoretical vertical line, and in copper In the bushing revolution, the spindle assembly can rotate in the eccentric copper sleeve with the center line of the spindle. When the air machine runs, the eccentric sleeve “holds” the spindle assembly and turns with the large gear. When the material is added to the crushing chamber, the spindle assembly (main shaft, inner cone) is slowly rotating in the eccentric copper sleeve under the resistance of the material. The running trajectory of the inner cone appears to swing back and forth in the crushing cavity and slowly rotate at the same time. The material is squeezed and broken by the wobble inner cone. When the connection between the support sleeve and the frame is pressed by the hydraulic cylinder, when the crusher falls into the metal block and so on, the moving cone of the single cylinder is taken up by the hydraulic piston at the bottom.

If you want to learn more about our crushing equipment, Leave a Message!

If you want to learn more about our crushing equipment, Leave a Message!

Technical Data

Fine crushing single cylinder hydraulic cone crusher technical data

| Model | stroke | Max. feeding size(mm) | Weight(kg) | Power(kw) | Discharge size(mm) with capacity(TPH) | |||||||

| 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | |||||

| GPD100 | 16 | 40-150 | 5800 | 75-90 | 40-50 | 45-58 | 60-70 | 80-90 | 85-95 | |||

| 20 | 40-150 | 5800 | 75-90 | 50-58 | 50-60 | 70-80 | 95-105 | |||||

| 25 | 40-150 | 5800 | 75-90 | 58-65 | 75-90 | 105-120 | ||||||

| GPD200 | 18 | 40-210 | 9300 | 110-160 | 60-70 | 70-90 | 80-105 | 100-125 | 135-150 | 160-175 | 185-200 | |

| 25 | 40-210 | 9300 | 110-160 | 90-110 | 110-130 | 130-158 | 160-180 | 185-210 | ||||

| 32 | 40-210 | 9300 | 110-160 | 140-160 | 170-190 | 190-220 | ||||||

| 40 | 40-210 | 9300 | 110-160 | 200-220 | 220-240 | |||||||

| GPD300 | 25 | 40-260 | 13400 | 200-250 | 100-120 | 110-130 | 135-158 | 160-180 | 190-210 | 210-235 | 240-260 | |

| 32 | 40-260 | 13400 | 200-250 | 110-130 | 120-150 | 165-195 | 195-225 | 230-260 | 265-295 | 300-330 | ||

| 40 | 40-260 | 13400 | 200-250 | 150-170 | 205-230 | 245-275 | 290-320 | 325-358 | ||||

| GPD400 | 25 | 50-300 | 23500 | 220-315 | 130-150 | 158-175 | 180-200 | 210-230 | 230-258 | 260-280 | 330-350 | |

| 32 | 50-300 | 23500 | 220-315 | 140-170 | 185-215 | 215-245 | 250-280 | 285-315 | 320-350 | 410-430 | ||

| 40 | 50-300 | 23500 | 220-315 | 225-250 | 265-295 | 210-340 | 345-375 | |||||

| GPD500 | 25 | 50-300 | 26500 | 250-358 | 140-160 | 160-180 | 190-210 | 240-260 | 270-290 | 310-330 | 350-370 | |

| 32 | 50-300 | 26500 | 250-358 | 230-250 | 270-290 | 310-330 | 340-370 | 380-410 | 430-450 | |||

| 50-300 | 26500 | 250-358 | 290-310 | 320-340 | 380-410 | 430-460 | 480-510 | |||||

Medium Coarse Crushing Single Cylinder Hydraulic Cone Crusher Technical Data

| Model | stroke | Max. feeding size(mm) | Weight(kg) | Power(kw) | Discharge size(mm) with capacity(TPH) | ||||||

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | |||||

| GPD100S | 16 | 200-250 | 7350 | 75-90 | 80-90 | 105-115 | 120-130 | 135-145 | 145-165 | 158-175 | |

| 20 | 200-250 | 7350 | 75-90 | 120-130 | 145-158 | 160-180 | 170-200 | 185-215 | |||

| 25 | 200-250 | 7350 | 75-90 | 185-195 | 200-220 | 210-230 | |||||

| GPD200S | 18 | 250-330 | 10900 | 110-160 | 110-140 | 140-170 | 160-190 | 180-210 | 200-230 | 230-260 | |

| 25 | 250-330 | 10900 | 110-160 | 170-220 | 190-240 | 210-260 | 230-280 | ||||

| 32 | 250-330 | 10900 | 110-160 | 230-280 | 270-320 | 280-350 | |||||

| GPD300S | 18 | 280-380 | 16200 | 132-250 | 170-190 | 170-210 | 190-230 | 210-258 | 235-275 | 258-295 | |

| 25 | 280-380 | 16200 | 132-250 | 220-270 | 258-315 | 290-345 | 320-350 | 330-350 | |||

| 32 | 280-380 | 16200 | 132-250 | 360-400 | 380-420 | 400-440 | |||||

| 40 | 280-380 | 16200 | 132-250 | 450-500 | 480-530 | ||||||

Coarse Crushing Single Cylinder Hydraulic Cone Crusher Technical Data

| Model | stroke | Max. feeding size(mm) | Weight(kg) | Power(kw) | Discharge size(mm) with capacity(TPH)PH) | ||||||

| 45 | 50 | 58 | 60 | 65 | 70 | 75 | |||||

| GPD500S | 18 | 380-500 | 33300 | 200-358 | 300-350 | 325-375 | 375-425 | 400-650 | 425-475 | 450-500 | 500-580 |

| 25 | 380-500 | 33300 | 200-358 | 500-580 | 580-600 | 600-650 | 650-700 | 700-750 | 750-800 | ||

| 32 | 380-500 | 33300 | 200-358 | 650-700 | 700-750 | 750-800 | 825-875 | 900-950 | |||

| 40 | 380-500 | 33300 | 200-358 | 900-950 | 975-1050 | ||||||

Note: This is just reference. Please contact us to get price and details.