Ball Mill

Applied Materials:

Quartzite, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, construction waste, glass, etc.

Applications:

Cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramics production industries.

If you want to learn more about our beneficiation equipment, Leave a Message!

Introduction of Ball Mill

The ball mill is suitable in the powder rubs each kind of ore and other materials, the balll mill is widely used in the dressing, professions, building materials and chemical industry and so on. It is divided into two rubbing way-the dry and the wet .There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. The ball mill is a key equipment to grind the crushed materials after the material were broken , and carrying on the smashing again. and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc,the ball mill carries on the dry type or the wet powder to each kind of ore and other grindability material rubs.

If you want to learn more about our beneficiation equipment, Leave a Message!

Application of Ball Mill

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

The ball mill is suitable for the beneficiation and grinding of fly ash, limestone, quartz sand, aluminium powder, coal powder, steel slag, ore, potassium feldspar, iron ore, iron slag, aluminium slag, silicon carbide, alumina, coal gangue and other materials.

Working Principle of Ball Mill

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

If you want to learn more about our beneficiation equipment, Leave a Message!

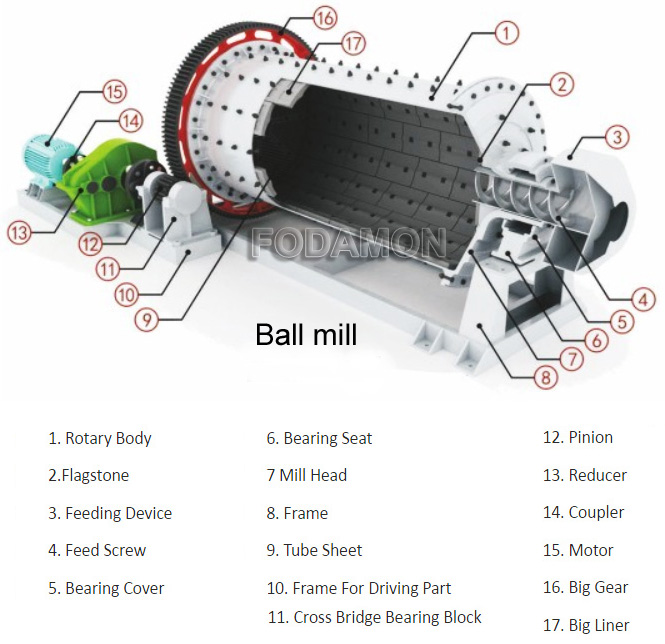

Structure of Ball Mill

Why choose Fodamon Ball Mill?

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical Data

|

Model |

Feeding size |

Discharging size |

Capacity |

Motor power |

Total Weight |

|

Ф900×1800 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

5.8 |

|

Ф900×3000 |

≤20 |

0.075-0.89 |

1.1-3.5 |

22 |

6.8 |

|

Ф1200×2400 |

≤25 |

0.075-0.6 |

1.5-4.8 |

30 |

12 |

|

Ф1200×3000 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

13.2 |

|

Ф1200×4500 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

13.7 |

|

Ф1500×3000 |

≤25 |

0.074-0.4 |

2-5 |

75 |

16.5 |

|

Ф1500×4500 |

≤25 |

0.074-0.4 |

3-6 |

110 |

21 |

|

Ф1500×5700 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

24.7 |

|

Ф1830×3000 |

≤25 |

0.074-0.4 |

4-10 |

130 |

34.5 |

|

Ф1830×4500 |

≤25 |

0.074-0.4 |

4.5-12 |

155 |

38 |

|

Ф1830×6400 |

≤25 |

0.074-0.4 |

6.5-15 |

210 |

46 |

|

Ф1830×7000 |

≤25 |

0.074-0.4 |

7.5-17 |

245 |

49 |

|

Ф2100×3000 |

≤25 |

0.074-0.4 |

6.5-36 |

155 |

48 |

|

Ф2100×4500 |

≤25 |

0.074-0.4 |

8-43 |

245 |

59 |

|

Ф2100×7000 |

≤25 |

0.074-0.4 |

8-48 |

280 |

67.5 |

|

Ф2200×4500 |

≤25 |

0.074-0.4 |

9-45 |

280 |

58 |

|

Ф2200×6500 |

≤25 |

0.074-0.4 |

14-26 |

380 |

63 |

|

Ф2200×7000 |

≤25 |

0.074-0.4 |

15-28 |

380 |

65.3 |

|

Ф2200×7500 |

≤25 |

0.074-0.4 |

15-30 |

380 |

66.5 |

|

Ф2400×3000 |

≤25 |

0.074-0.4 |

7-50 |

245 |

65 |

|

Ф2400×4500 |

≤25 |

0.074-0.4 |

8.5-60 |

320 |

70 |

|

Ф2700×4000 |

≤25 |

0.074-0.4 |

12-80 |

400 |

92 |

|

Ф2700×4500 |

≤25 |

0.074-0.4 |

12-90 |

430 |

102 |

|

Ф3200×4500 |

≤25 |

0.074-0.4 |

Determined by the technological process |

600 |

137 |

|

Ф3600×4500 |

≤25 |

0.074-0.4 |

Determined by the technological process |

850 |

158 |

|

Ф3600×6000 |

≤25 |

0.074-0.4 |

Determined by the technological process |

1250 |

175 |

Note: This is just reference. Please contact us to get suitable solution and competitive price