Three Cylinder Dryer

Applied Materials:

Sand, Slag, Clay, Flyash, Coal and other materials with small particle size and good fluidity.

Applications:

Iron powder, mineral powder and other mixed materials, dry mixed mortar and yellow sand in construction industry, and drying of raw materials in chemical industry, casting and other industries.

If you want to learn more about our drying equipment, Please Leave a Message!

Introduction of Three Cylinder Dryer

The rotary three drum dryer improves the internal structure of the original single drum dryer, increases the pre drying of wet materials before entering the dryer and prolongs the drying time of wet materials in the dryer. Coupled with sealing, thermal insulation and reasonable supporting measures, the production capacity of the dryer is increased by 48-80% compared with the original single drum dryer, the evaporation intensity per unit volume can reach 120-180kg / m3, and the standard coal consumption is only 6-8kg / T. With advanced technology, reasonable operating parameters and simple and feasible operation, it is widely used in slag, clay and coal in various industries.

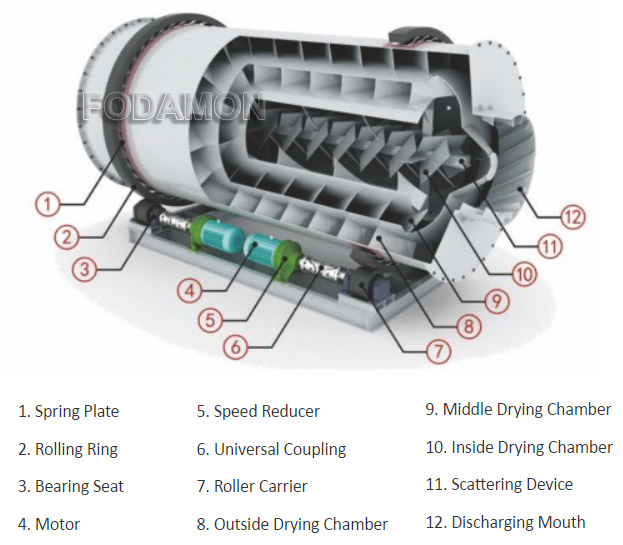

Structure of Three Cylinder Dryer

Three cylinder dryer changes the single cylinder of the single cylinder dryer into three cylinders stacked together, so as to shorten the overall dimension of the dryer body. When the machine works, the materials and hot air flow enter the inner to outer cylinder in turn. After the Z-shaped reciprocating baffle of the machine body, the materials are dried by making full use of heat energy and then discharged. The cylinder part of the dryer is composed of three coaxial and horizontally placed inner, middle and outer cylinders, which makes full use of the cross section of the cylinder. The total length of the cylinder shape is about 30-35% of the equivalent single cylinder. So as to greatly reduce the floor area and plant construction area. The supporting device of the machine is supported by the wheel belt and supporting wheel on the outer cylinder, and the supporting wheel is directly driven by the motor. The cylinder rotates through the friction between the supporting wheel and the wheel belt. The overall structure of the machine is compact, reasonable and simple. In order to facilitate the maintenance and replacement of wear parts, it is designed into an axial split type in the middle and fixed and connected with bolts.

If you want to learn more about our drying equipment, Please Leave a Message!

If you want to learn more about our drying equipment, Please Leave a Message!

Technical Parameter of Three Cylinder Dryer

|

Model |

Diameter(m) |

length(m) |

Process Capacity(t/h) |

Rotary speed (r/min) |

Power kw |

||

|

Sand |

Flyash |

Slag |

|||||

|

Ф1.6×1.8 |

1.6 |

1.8 |

2-3 |

1-2 |

2-3 |

3-10 |

3 |

|

Ф2×2 |

2 |

2 |

4-5 |

2-3 |

4-5 |

3-10 |

4 |

|

Ф2.2×2.5 |

2.2 |

2.5 |

8-10 |

4-5 |

8-10 |

3-10 |

5.5 |

|

Ф2.5×2.8 |

2.5 |

2.8 |

12-15 |

6-8 |

12-15 |

3-10 |

11 |

|

Ф2×3 |

2 |

3 |

8-12 |

4-6 |

8-12 |

3-10 |

3×2 |

|

Ф2×5 |

2 |

5 |

12-15 |

6-8 |

12-15 |

3-10 |

5.5×2 |

|

Ф2.2×4.5 |

2.2 |

4.5 |

15-18 |

8-10 |

15-18 |

3-10 |

5.5×2 |

|

Ф2.5×5 |

2.5 |

5 |

20-25 |

10-13 |

20-25 |

3-10 |

4×4 |

|

Ф2.5×6 |

2.5 |

6 |

25-30 |

13-15 |

25-30 |

3-10 |

5.5×4 |

|

Ф2.8×6 |

2.8 |

6 |

30-35 |

15-18 |

30-35 |

3-10 |

7.5×4 |

|

Ф3×6 |

3 |

6 |

35-40 |

18-20 |

35-40 |

3-10 |

7.5×4 |

|

Ф3×7 |

3 |

7 |

40-45 |

20-23 |

40-45 |

3-10 |

11×4 |

|

Ф3.2×7 |

3.2 |

7 |

45-50 |

23-25 |

45-50 |

3-10 |

11×4 |

|

Ф3.2×8 |

3.2 |

8 |

50-55 |

25-28 |

50-55 |

3-10 |

11×4 |

|

Ф3.6×8 |

3.6 |

8 |

55-60 |

28-30 |

55-60 |

3-10 |

15×4 |

|

Ф3.8×9 |

3.8 |

9 |

60-70 |

30-35 |

60-70 |

3-10 |

15×4 |

|

Ф4.0×10 |

4 |

10 |

70-100 |

35-50 |

70-100 |

3-10 |

18.5×4 |

|

Ф4.2×8.5 |

4.2 |

8.5 |

80-100 |

40-50 |

80-100 |

3-10 |

18.5×4 |

Note: This is just reference. Please contact us to get suitable solution and competitive price.