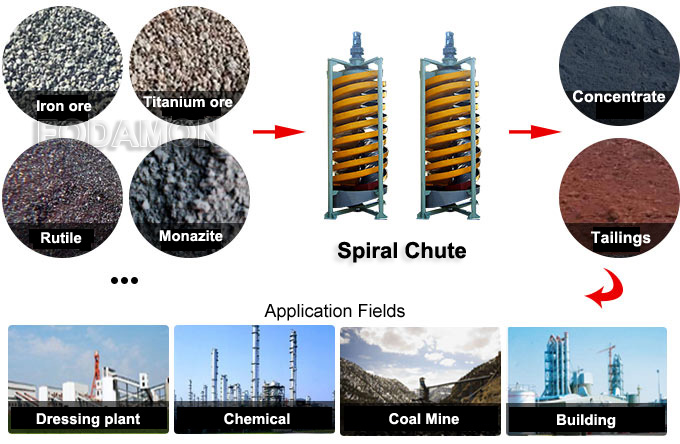

Spiral Chute

Applied Materials:

Copper ore, zinc ore, aluminum ore, pyrrhotite, hematite, limonite, pyrite, ilmenite, tungsten ore, molybdenum ore, gold ore, iron ore, etc.

Applications:

Production industries such as cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics.

If you want to learn more about our beneficiation equipment, Leave a Message!

Introduction of Spiral Chute

Introduction of Spiral Chute

This equipment is suitable for the separation of iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphonite, tungsten ore, tin ore, strontium with a particle size of 0.3–0.02 mm. Mines, antimony ore and other non-ferrous metals, rare metals and non-metallic mineral bodies with different specific gravity. The equipment has a stable and easy control process, and the concentration of the ore concentration is allowed to vary, the enrichment ratio is high, the recovery rate is high, the floor space is small, the water consumption is small, the structure is simple, no power is required, the processing capacity is large, and the installation is simple. Easy to operate, small investment and quick results.

Advantages of Fodamon Spiral Chute

Advantages of Fodamon Spiral Chute

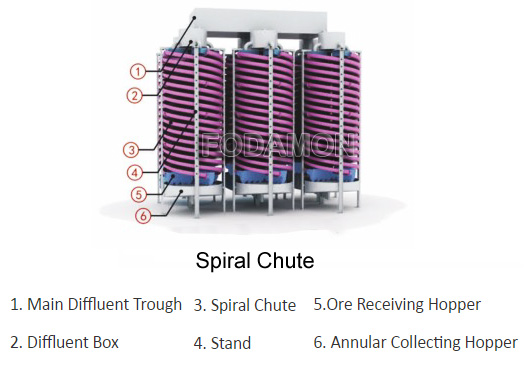

1. Small footprint and large processing capacity. The structure is reasonable, the installation is simple, the floor space is small, the operation is simple, the ore dressing is stable, the mine is clear, the treatment volume is large, the efficiency is high, the ore dressing enrichment ratio is high, the recovery rate is high, and the operation is reliable.

2. Light weight and no noise. It is light in weight, moisture-proof, rust-proof and corrosion-resistant. It has strong adaptability to fluctuations in the amount of ore and concentration, grain size and grade, and has no noise.

3. Easy to operate and adaptable. The spiral chute is not critical to the operation requirements (such as the ore size, mass fraction, etc.), even if the ore supply, ore concentration, ore size and ore grade change, there is almost no influence on the selection index, and it has strong adaptability.

4. The treatment effect is good. The spiral chute is not only easy to operate, but also achieves a good treatment effect. It is characterized by stable ore dressing, clear ore separation, large processing capacity, high efficiency, and high enrichment ratio.

If you want to learn more about our beneficiation equipment, Leave a Message!

Working Principle

Raise the spiral chute, calibrate the vertical line, fix it in the appropriate position with iron frame or wood, send the ore to the top of the spiral feed by the sand pump, add the supplementary water, adjust the concentration of the ore paddle, the natural paddle Swirl from high to low, generating an inertial centrifugal force in the rotating bevel flow rate. Separating the ore from the sand by the gravity and centrifugal force of the swirling flow, the difference in specific gravity, grain size and shape of the ore. The flow into the concentrate bucket is taken out by the pipeline, and the tail sand flows into the sand pond with the pipeline, and then drained by the sand pump to complete the whole process of the beneficiation.

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical Data

|

Model |

Processing capacity (t/h) |

|

DL2000 |

15-40 |

|

DL1500 |

8-16 |

|

LL1200 |

4-6 |

|

LL900 |

2-3 |

Note: This is just reference. Please contact us to get price and details.