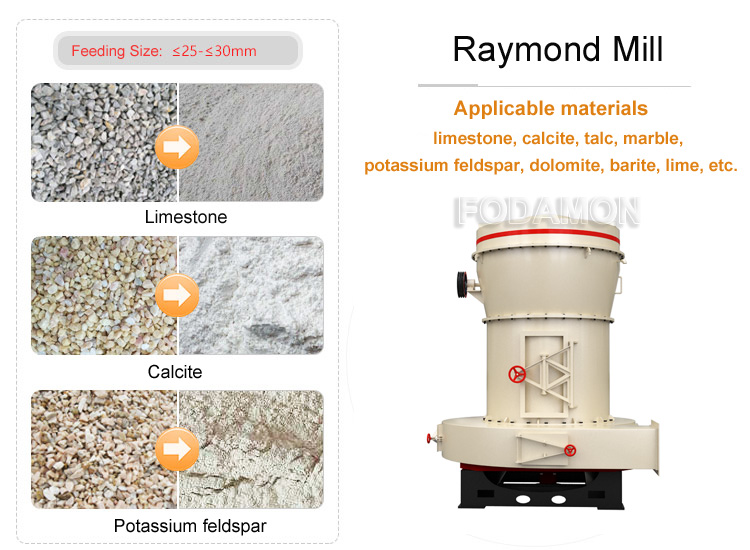

Raymond Mill

Applied Materials:

Limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartzite, bentonite, etc.

Applications:

Crushing of calcium carbonate, processing of gypsum powder, desulfurization of power plants, milling of non-metallic minerals and preparation of pulverized coal.

If you want to learn more about our powder making equipment, Leave a Message!

Introduction of Raymond Mill

Introduction of Raymond Mill

Raymond mill is widely used in the processing of 280 kinds of materials, such as dolomite, limestone, potash feldspar, barite, calcite, talc, marble, fluorite, activated clay, activated carbon, bentonite, kaolin, cement, gypsum, glass, etc., with Mohs hardness no more than 9.3 and humidity less than 6%. R-Raymond mill The particle size of the finished powder machine can be adjusted within 80-325 mesh range, and some materials can reach 600 mesh. Our factory’s grinding mill series include Raymond Mill, High Pressure Grinding Mill, Europe Version Grinding Mill, Superfine Pulverizer Mill, etc.

If you want to learn more about our powder making equipment, Leave a Message!

Structural composition of Raymond Mill

Structural composition of Raymond Mill

The structure of the machine is mainly composed of main machine, analyzer, fan, finished cyclone separator, micro powder cyclone separator and air duct. The main engine is composed of frame, air inlet volute, blade, grinding roller, grinding ring and cover.

If you want to learn more about our powder making equipment, Leave a Message!

Working Principle of Raymond Mill

Working Principle of Raymond Mill

After the material is ground, the fan blows the air into the main machine shell, blows up the powder, and sorts it through the analyzer placed above the grinding chamber. The material with too fine and too coarse falls into the grinding chamber for regrinding, and the material with the fineness conforming to the specification flows into the cyclone collector with the wind flow, and is discharged through the powder outlet after collection, which is the finished product. The air flow is returned to the fan by the return air pipe at the upper end of the large cyclone collector. The air path is circulating and flows under the negative pressure state. The air volume increase part of the circulation air path is discharged through the exhaust gas pipe between the fan and the host, and enters the small cyclone collector for purification.

If you want to learn more about our powder making equipment, Leave a Message!

Technical Parameter of Raymond Mill

|

Model |

3R1410 |

3R2115 |

3R2615 |

3R2715 |

4R2715 |

3R3016 |

4R3016 |

3R3019 |

4R3019 |

4R3216 |

5R4119 |

|

Max.feedsize(mm) |

8 |

15 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

25 |

30 |

|

Final size(mesh) |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

80-325 |

|

Speed(r/m) |

240 |

180 |

160 |

160 |

160 |

150 |

150 |

150 |

150 |

140 |

105 |

|

Inner diameter of ring(mm) |

435 |

630 |

780 |

820 |

820 |

890 |

890 |

890 |

890 |

970 |

1280 |

|

Diameter of roller(mm) |

140 |

210 |

260 |

270 |

270 |

300 |

300 |

300 |

300 |

320 |

410 |

|

Height of roller(mm) |

110 |

150 |

150 |

150 |

150 |

160 |

160 |

190 |

190 |

160 |

190 |

|

Main motor(kw) |

7.5 |

15 |

18.5 |

22 |

22 |

30 |

37 |

30 |

37 |

45 |

75 |

|

Fan motor(kw) |

5.5 |

11 |

15 |

18.5 |

18.5 |

22 |

30 |

22 |

30 |

37 |

75 |

|

Analytical motor (kw) |

1.1 |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

5.5 |

3 |

5.5 |

5.5 |

7.5 |

|

Capacity(ton/shift) |

0.5-1.5 |

1-2 |

1.5-2.5 |

1.5-3 |

1.5-3.5 |

2-5 |

2-6 |

3-8 |

3.5-8.5 |

4-10 |

6-15 |

Note: This is just reference. Please contact us to get suitable solution and competitive price.