High Pressure Suspension Mill

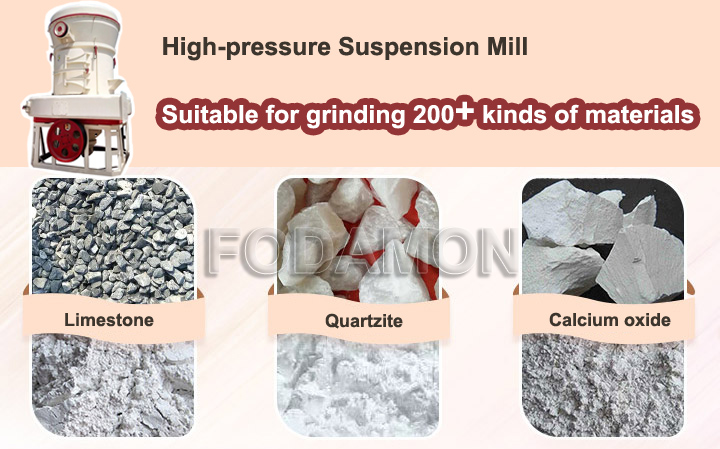

Applied Materials:

Limestone, calcite, calcium carbonate, dolomite, barite, talc, potash feldspar, fly ash, kaolin, quartzite, coke, coal gangue, etc.

Applications:

Crushing of calcium carbonate, processing of gypsum powder, desulfurization of power plants, milling of non-metallic minerals and preparation of pulverized coal.

If you want to learn more about our powder making equipment, Leave a Message!

Introduction of High Pressure Suspension Mill

Introduction of High Pressure Suspension Mill

High-pressure Roller Mill is suitable for crushing over 280 kinds of materials in the industry of mining, metallurgy, chemical industry, building materials, etc. with the Mohs hardness of barite, limestone, ceramics, slag not more than 9.3 and the humidity below 8%. The particle size of the finished product is adjusted within the scope of 80-600 items. High pressure roller mill can produce 30-80 mesh coarse powder through special device added in the mill.

Advantages of Fodamon High Pressure Suspension Mill

1. Compared with other mills, the output is increased by 10-20% under the same power condition, and the grinding pressure of grinding roller to materials is increased by 800-1200kg under the action of high pressure spring.

2. Mineral materials with Mohs hardness less than 9.3 can be processed and crushed.

3. The particle size range of the finished product is wide. The particle size can reach 0.613 mm (30 mesh), 0.033 mm (425 mesh) in general, and 0.013 mm (1000 mesh) in a few materials.

4. The dust removal effect completely meets the national dust emission standard.

5. The analyzer is easy to adjust.

6. The lapping device adopts overlapping multi-stage seal with good sealing performance.

Working Principle

A high-pressure spring with a pressure of 1000-1500 kg is fastened on the roller hanger of the high-pressure suspension roller mill. After starting to work, the grinding roller rotates around the main shaft, and rolls against the grinding ring under the action of high-pressure spring and centrifugal force. Its rolling pressure is 1.2 times higher than that of Raymond powder machine under the same power condition, so the output is greatly increased. When the ground material enters into the grinding chamber, it is scooped by the blade and sent to the grinding roller and the grinding ring for rolling. The rolled powder is brought into the analyzer along with the circulating air of the blower. The qualified fine powder flows into the cyclone powder collector along with the air, which is the finished product. The large particles fall back to the grinding. The circulation air returns to the blower and repeats the above process, and the remaining air enters the bag filter for purification. When the grinding roller and the grinding ring reach a certain wear, adjust the length of the high-pressure spring to maintain a constant rolling pressure between the grinding roller and the grinding ring, so as to ensure a stable output and fineness.

If you want to learn more about our powder making equipment, Leave a Message!

If you want to learn more about our powder making equipment, Leave a Message!

High Pressure Suspension Mill Technical Data

| Model |

Quantity of roller (pcs) |

Diameter and Height of roller |

Diameter and Height of ring |

Feeding size |

Product size (mm) |

Capacity (t/h) |

Power(kW) |

Overall size |

|

M+B+C |

||||||||

|

YGM65 |

3 |

210×150 |

650×150 |

≤15 |

0.613-0.033 |

0.4-1.8 |

15+11+2.2 |

4100×3300×4500 |

|

YGM75 |

3 |

260×150 |

780×150 |

≤15 |

0.613-0.033 |

1-3 |

18.5+15+2.2 |

4300×3500×5100 |

|

YGM85 |

3 |

270×150 |

830×150 |

≤20 |

0.613-0.033 |

1.2-4 |

22+22+4 |

5300×4100×5200 |

|

YGM95 |

4 |

310×190 |

950×190 |

≤25 |

0.613-0.033 |

2.1-5.6 |

37+30+5.5 |

7100×5900×7900 |

|

YGM130 |

5 |

410×230 |

1280×230 |

≤30 |

0.613-0.033 |

2.5-9.5 |

75+75+7.5 |

7900×8000×9700 |

|

YGM160 |

6 |

450×300 |

1600×300 |

≤35 |

0.613-0.033 |

8-16 |

132+110+11 |

12550×5700×8355 |

|

YGM190 |

6 |

500×330 |

1900×330 |

≤40 |

0.613-0.033 |

18-36 |

200+200+30 |

11200×8530×9685 |

|

Note: M for Main Unit, B for Blower, C for Classifier of the Mill |

||||||||

High Pressure Micro Powder Mill Technical Data

|

Model |

YGM7826 |

YGM8327 |

YGM9531 |

|

Quantity of roller (pcs) |

3 |

3 |

4 |

|

Diameter of roller (mm) |

Φ260 |

Φ270 |

Φ310 |

|

Inner diameter of ring(mm) |

Φ780 |

Φ830 |

Φ950 |

|

Rotary speed of main unit (r/min) |

160 |

140 |

130 |

|

Feeding size (mm) |

< 20 |

||

|

Capacity (kg/h) |

22-500 |

30-680 |

150-1000 |

|

Motor of main unit (kW) |

Y225M-8-18.5 |

Y225M-8-22 |

Y225S-4-37 |

|

Motor of blower (kW) |

Y160L-4-15 |

Y180M-4-18.5 |

Y200L-4-30 |

|

Motor of classifier (kW) |

Y160M-6-7.5 |

Y160M-6-7.5 |

YCT200-4A-7.5 |

|

Overall size (LxWxH) (mm) |

4.5×4.2×5.1 |

5.3×4.1×5.2 |

7.1×5.9×7.9 |

|

Product size (mm) |

500 mesh (0.025)—1250 mesh (0.01) , maximum 2500 mesh (0.005) |

||

Note: This is just reference. Please contact us to get price and details.