Mesh Belt Drying Machine

Applied Materials:

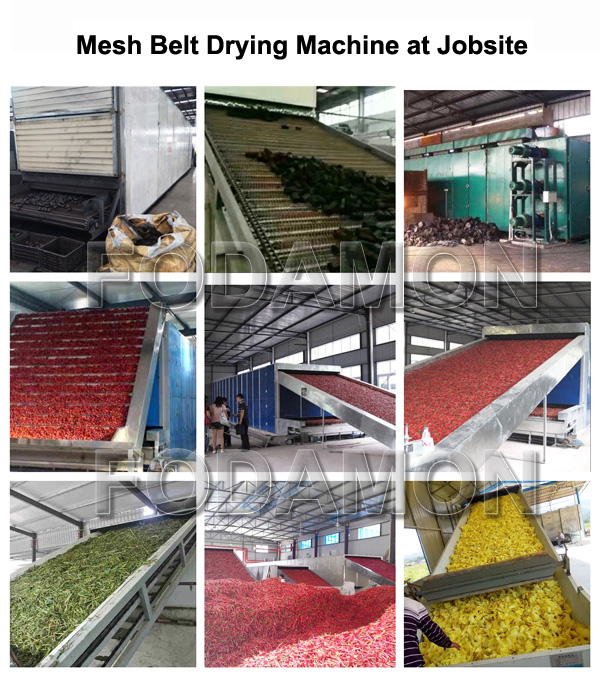

Block, slice, strip, granular and other materials: briquette, animal husbandry, palm silk, hair, shavings, vegetables, food

Applications:

Widely used in chemical, animal husbandry, food, medicine, building materials, electronics and other industries, especially suitable for air permeable sheet, strip, granular materials drying, paste cake materials, also through granulator or extruder molding materials for drying

If you want to learn more about our mesh belt drying machine, Leave a Message!

Introduction of Mesh Belt Drying Machine

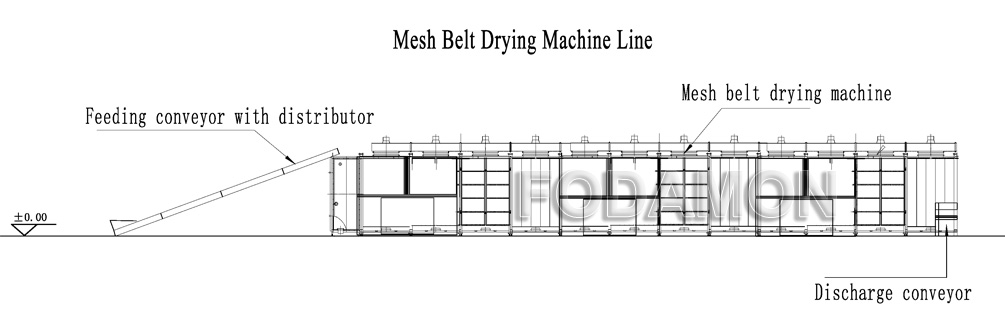

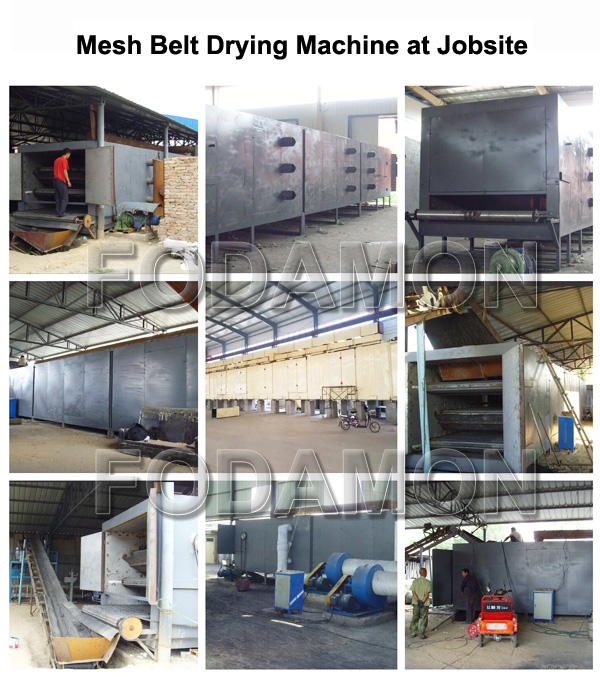

Mesh belt dryer is a kind of drying equipment for batch and continuous production. The main heating methods are electric heating, steam heating and hot air heating. The main principle is that the material is evenly laid on the mesh belt, the mesh belt uses 12-60 mesh steel wire mesh belt, driven by the transmission device in the dryer to move back and forth, hot air flowing through the material, steam discharged from the dehumidification hole, so as to achieve the purpose of drying, the length of the box is composed of standard section, in order to save space. The dryer can be made into a multi-layer dryer. The common dryers are two rooms, three layers, two rooms and five layers, with a length of 6-40m and an effective width of 0.6-3.0m. Depending on the material to be dried, we have mesh belt dryers for drying briquettes, plants, food, etc.

Advantages of Fodamon Mesh Belt Conveyor Dryer

Working Principle

If you want to learn more about our mesh belt drying machine, Leave a Message!

If you want to learn more about our mesh belt drying machine, Leave a Message!

Technical Data

|

Model |

202 |

204 |

304 |

306 |

|

Effective working length of monolayer (m) |

20 |

20 |

30 |

30 |

|

Number of layers (n) |

2 |

4 |

4 |

6 |

|

Effective working width (m) |

1.2 |

1.2 |

1.5 |

1.5 |

|

Average stacking thickness of materials (mm) |

200 |

|||

|

Drying capacity(t/h) |

6 |

10 |

15 |

20 |

|

Moisture content before drying (%) |

8-12% |

8-12% |

8-12% |

8-12% |

|

Moisture content after drying (%) |

1.5-3% |

1.5-3% |

1.5-3% |

1.5-3% |

|

Transfer power (kw) |

3 |

3×2 |

5.5×2 |

5.5×3 |

|

Hot air temperature requirements (℃) |

180-250 |

|||

|

Hot air content requirement (kg/kg) |

≤0.01kg/kg Dry air |

|||

Note: This is just reference. Please contact us to get price and details.