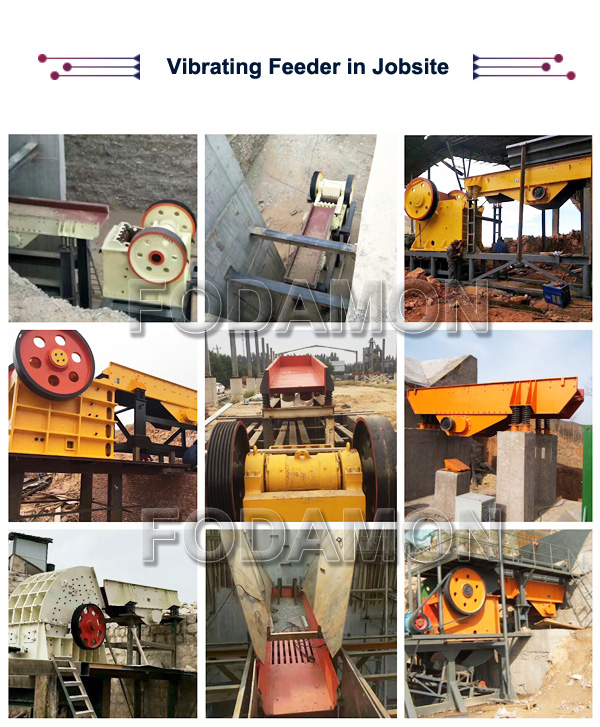

Vibrating Feeder

Applied Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Applications:

Metallurgical, chemical, building materials, electricity, transportation and other industrial sectors.

If you want to learn more about our vibrating feeder, Leave a Message!

Vibrating feeder, also known as feeder, can evenly, regularly and continuously feed block and granular materials from the storage bin to the receiving device. In the gravel production line, it can continuously and evenly feed the crushing machinery and coarse screen the materials. It can feed materials to belt conveyor, bucket elevator, screening equipment, crusher, crusher, etc. and it can also be used for automation Batching, quantitative packaging, etc., and can be used in the automatic control process to achieve the automation of the production process. Feeder is divided into vibration feeder, electromagnetic vibration feeder, etc. The vibrating feeder is mainly composed of rib plate, lining plate, spring, castor bar, vibrator, etc.

Vibrating feeder, also known as feeder, can evenly, regularly and continuously feed block and granular materials from the storage bin to the receiving device. In the gravel production line, it can continuously and evenly feed the crushing machinery and coarse screen the materials. It can feed materials to belt conveyor, bucket elevator, screening equipment, crusher, crusher, etc. and it can also be used for automation Batching, quantitative packaging, etc., and can be used in the automatic control process to achieve the automation of the production process. Feeder is divided into vibration feeder, electromagnetic vibration feeder, etc. The vibrating feeder is mainly composed of rib plate, lining plate, spring, castor bar, vibrator, etc.

If you want to learn more about our vibrating feeder, Leave a Message!

Working Principle

Working Principle

The vibrating feeder uses the eccentric block rotation in the vibrator to generate centrifugal force, so that the movable parts such as screen chamber and vibrator can make forced continuous circle or approximate circle movement. Vibrating feeder is composed of feeding tank, exciter, spring support, transmission device, etc. The vibration source of the tank vibration feeding is the exciter, which is composed of two eccentric shafts (active and passive) and gear pairs. The motor drives the active shaft through the triangle belt, and then the gears on the active shaft engage with the passive shaft to rotate. The active and passive shafts rotate in reverse at the same time, making the tank vibrate, making the materials flow continuously, so as to achieve the purpose of conveying materials.

If you want to learn more about our vibrating feeder, Leave a Message!

Technical Parameter of Vibrating Feeder

|

Motel |

Max feed size(mm) |

Capacity |

Motor power |

Obliquity of material trough |

Total Weight |

Trough size(mm) |

Dimensions |

|

GZD650x2300 |

300 |

80 |

1.5×2 |

10 |

2798 |

650×2300 |

2300x1360x780 |

|

GZD-750×2500 |

350 |

100 |

1.5×2 |

10 |

3260 |

750×2500 |

2500x1460x780 |

|

GZD-850×3000 |

400 |

120 |

3×2 |

10 |

3607 |

850×3000 |

3110x1800x1600 |

|

GZD-1000×3600 |

500 |

150 |

5.5×2 |

5 |

3895 |

1000×3600 |

3850x1950x1630 |

|

GZD-1100×4200 |

580 |

240 |

5.5×2 |

5 |

4170 |

1100×4200 |

4400x2050x1660 |

|

GZD-1100×4900 |

580 |

280 |

7.5×2 |

5 |

4520 |

4900×1100 |

5200x2050x1700 |

|

GZD-1300×4900 |

650 |

450 |

11×2 |

5 |

5200 |

1900×1300 |

5200x2350x1750 |

|

ZSW-380×95 |

500 |

96-160 |

11 |

0 |

4082 |

3800×960 |

3920x1640x1320 |

|

ZSW-490×110 |

630 |

120-280 |

15 |

0 |

5352 |

4900×1100 |

4980x1830x1320 |

|

ZSW-600×130 |

750 |

400-560 |

22 |

0 |

7800 |

6000×1300 |

6082x2580x2083 |

Note:This is just reference. Please contact us to get suitable solution and competitive price.