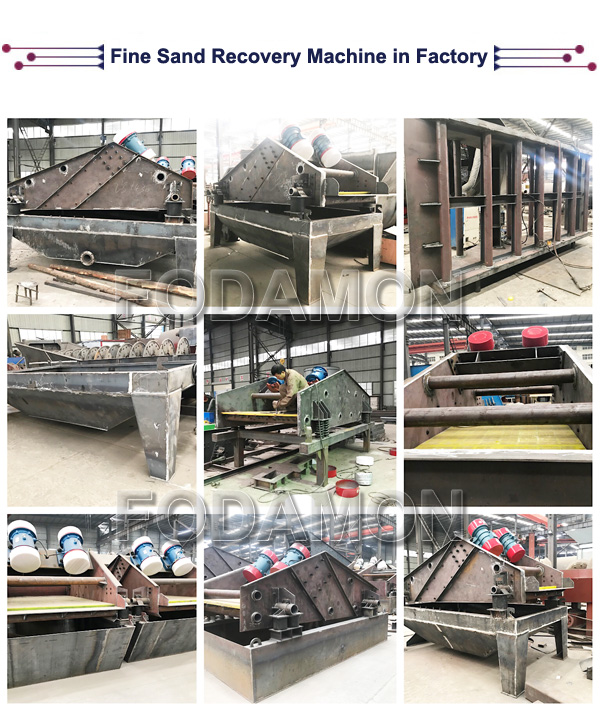

Fine Sand Recovery Machine

Applied Materials:

kaolin, mud, sand and gravel aggregate, artificial sand, coarse slime, concrete mixing station and other fine materials recycling and reuse.

Applications:

It is used for mud purification, sand aggregate aggregate system, raw material processing system, artificial sand production line, and coarse coal slurry recovery in coal preparation plant.

If you want to learn more about our fine sand recovery machine, Leave a Message!

Introduction of Fine Sand Recovery Machine

Introduction of Fine Sand Recovery Machine

The fine sand extractor is also called fine sand collector, fine sand recovery machine, fine sand recovery machine, fine sand recovery device, and fine sand recovery equipment. At present, most of the existing artificial mechanism sand production line adopts wet process technology. No matter which type of sand washing machine is used, the biggest disadvantage is that the fine sand (below 0.2mm particles) has a serious loss problem, and some even lose more than 20%. This not only loses production, but also seriously affects the gradation of sand, resulting in unreasonable gradation and increased fineness modulus, which greatly reduces the quality of manufactured sand products. In concrete mixing, it not only increases the amount of cement, but also increases the cost of the business, and the excessive emission of fine sand will cause the waste of land resources and the pollution of the environment. In view of the above problems, our company has successfully developed a FDMX series of fine sand recovery equipment. This equipment is a high-tech environmental protection equipment specially designed by our company to absorb advanced technology from foreign countries and combine the actual production of fine sand in the actual production of customers. In the actual application, the fine sand recovery machine does not need additional water consumption. It can extract more than 85% of the fine sand or ore which have been washed away from the original waste water. It can be directly added into the finished product pile or separate storage as a high grade material, and directly restores more than 15% of the comprehensive economic benefits for the customers.

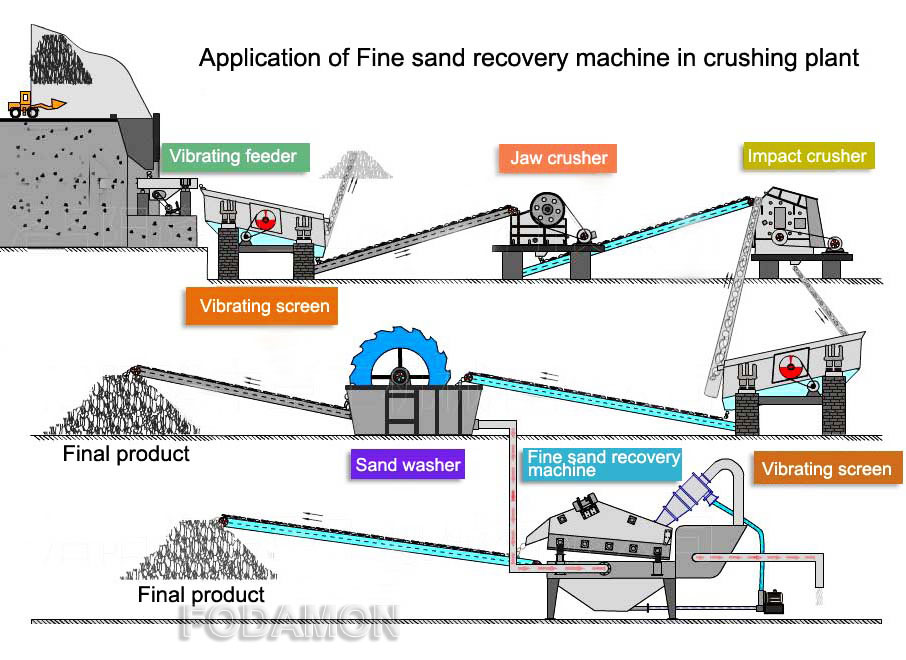

Application of Fine Sand Collector

The equipment is widely used in the processing system of sand and stone aggregate of the hydropower station, the processing system of glass material, the production line of artificial sand, the recovery of coarse slime in the coal preparation plant, and the environmental protection engineering (mud purification, etc.), which can effectively solve the problem of the fine sand recovery of the production line.

If you want to learn more about our fine sand recovery machine, Leave a Message!

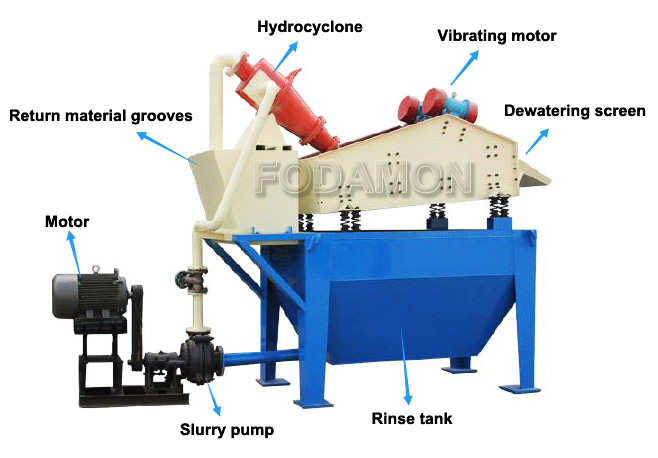

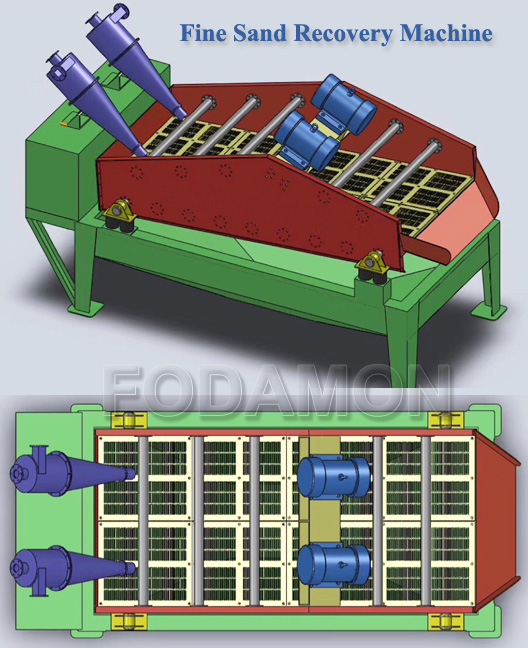

Structure of Fine Sand Recyling Machine

It has the following structural components: motor, vacuum high-pressure pump, sediment separator hydrocyclone, TS dewatering screen, cleaning tank and return box.

Working Principle of Fine Sand Recovery Machine

The special centrifugal Slag Pump conveyed the sand water mixture in the cleaning tank to the cyclone, and the fine sand by centrifugal classification was provided to the vibrating dewatering screen. After the vibrating screen was dewatered, the fine sand and water were separated effectively, a small amount of fine sand and mud returned to the Return material grooves , then returned to cleaning tank and returned to the cyclone. The mixture of the flow produces mixing and is sent to the cyclone again. When the liquid level of the cleaning tank is too high, it is discharged through the outlet. By changing the speed of the centrifugal pump, changing the mortar concentration, adjusting the overflow water and replacing the sand mouth to adjust the fineness modulus, the three functions of cleaning, dewatering and grading can be completed.

If you want to learn more about our fine sand recovery machine, Leave a Message!

Advantage of Fodamon Fine Sand Recovery Machine

If you want to learn more about our fine sand recovery machine, Leave a Message!

Fine Sand Recovery Machine Technical Data

|

Model |

Power of slurry pump(kw) |

Power of Dewatering screen (kw) |

Sewage treatment capacity (m³/h) |

Net size of screen surface of dewatering screen |

Quantity of cyclone |

Remarks |

|

XS250 |

7.5 |

0.75×2 |

30-40 |

800×2000 |

250×1 |

Single pump and single jet |

|

XS300 |

11 |

0.75×2 |

40-60 |

300×1 |

Single pump and single jet |

|

|

XS350 |

15 |

0.75×2 |

60-100 |

350×1 |

Single pump and single jet |

|

|

XS550 |

18.5 |

0.75×2 |

80-120 |

250×2 |

Single pump double jet |

|

|

XS550 |

18.5 |

0.75×2 |

80-120 |

1000×2000 |

250×2 |

Single pump double jet |

|

XS750 |

18.5×2 |

0.75×2 |

150-200 |

350×2 |

Double pump double jet |

|

|

XS750 |

18.5×2 |

1.5×2 |

240-300 |

1200×2500 |

350×2 |

Double pump double jet |

Note: This is just reference, please contact us to get suitable solution and competitive price.