Cement Mill

Applied Materials:

Limestone, stone powder, sand, cement clinker, bauxite, active lime, aluminum hydroxide and so on.

Applications:

Cement, silicate products, new building materials, refractories, glass ceramics and other production industries.

If you want to learn more about our beneficiation equipment, Leave a Message!

Introduction of Cement Mill

Introduction of Cement Mill

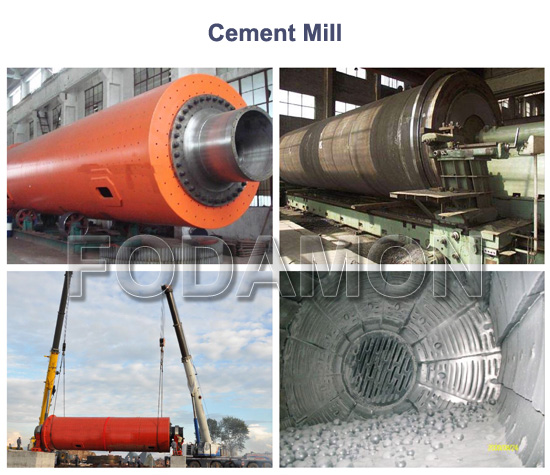

Cement mill is the key equipment for grinding again after cement clinker is pre crushed by system ingredients. Cement mill is mainly used in the production of cement silicate products. After exploring and summarizing the long-term design and production process, our company has formed a series of products with different specifications and different fineness requirements. In particular, the grinding of cement is more prominent.

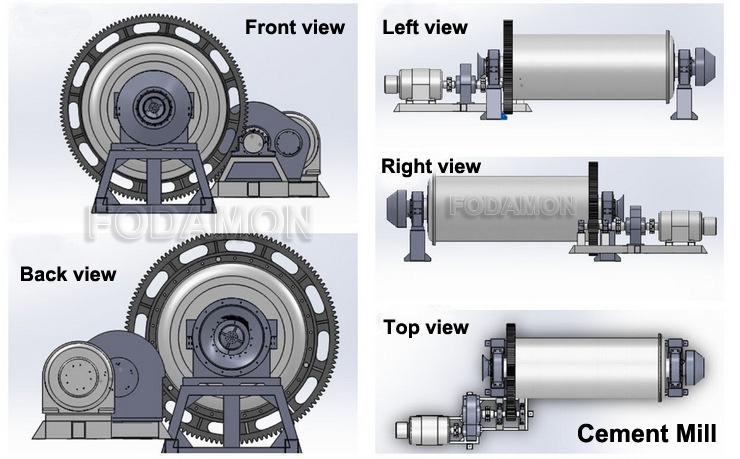

Our factory adopts suitable transmission modes for different types of cement mills, mainly including two ways: edge drive and center transmission. In the cylinder, the new grade liner and the standard step liner are used to increase the surface area of the material, and the effect of the classification is better, and the later maintenance and replacement are more simple. The new compartment structure adopts adjustable lifting plate and fixed lifting plate, which is easy to install and maintain.

Advantages of Fodamon Cement Mill

Advantages of Fodamon Cement Mill

1. The structure is simple and the operation is reliable. There is a lining board and plate lamp in the mill, which is simple in structure and reliable in operation.

2. Energy saving and durable. The bearing bush improves the bearing grinding, which has good energy saving effect, strong durability, low grinding cost and high yield.

3. The output is large. The mill output can be increased by 15-20% and the power consumption reduced by about 10% compared with the general mill. In addition, the finished product temperature can be reduced by 20-40 degrees C.

4. Good dust removal and long life. The dust removal performance of the mill is good and the pollution is few. The environmental protection standard is achieved. The renewal and development of the technology extend the service life of the wearing parts, and are easy to maintain and maintain.

Working Principle

Working Principle

When the mill barrel is driven by the transmission device, the abrasive body rotates with it on the lining surface of the inner wall of the mill barrel because of the action of the inertia centrifugal force. After being taken to a certain height, the abrasive is free to fall by the action of gravity. At this time the abrasive body breaks the material in the barrel, and the grinding body rises in the rotary mill. The movement of the falling cycle produces sliding and rolling, resulting in grinding between the abrasive, lining and grinding materials to make the material grind.

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical Data

|

Product specification |

Transmission form |

Gear box |

Motor power |

Production capacity |

Total weight |

|

|

Model |

Speed reduction ratio |

|||||

|

Φ1.83×7 |

Brim |

ZD60 |

4.5 |

245 |

6.5-8 |

43.8 |

|

Φ2.2×7.5 |

Brim |

ZD70 |

5 |

380 |

8-10 |

64.8 |

|

Φ2.2×11 |

Brim |

D110 |

35.5 |

630 |

12-13 |

104.6 |

|

Φ2.2×13 |

Brim |

D110 |

35.5 |

630 |

16-18 |

114 |

|

Φ2.4×13 |

Brim |

D110 |

35.5 |

800 |

20-23 |

130.6 |

|

Φ2.6×13 |

Brim |

MFY100 |

19.5 |

1000 |

28-32 |

158 |

|

Φ3×9 |

Brim |

D125 |

41.2 |

1000 |

28-36.5 |

167 |

|

Φ3×11 |

Brim |

D140 |

42.8 |

1250 |

36-47 |

180 |

|

Φ3.2×13 |

Brim |

D140 |

36.5 |

1600 |

45-50 |

225 |

|

Φ3.5×13 |

Brim |

JDX1000 |

5.84 |

2000 |

60-65 |

275 |

|

Φ3.8×13 |

Central shaft |

MFY250 |

16.5 |

2500 |

60-62 |

320 |

|

Φ4.2×13 |

Central shaft |

JQS3550 |

15.6 |

3530 |

85-87 |

380 |

|

Φ4.6×14 |

Central shaft |

JSI160-C |

14.6 |

4200 |

120-135 |

485 |

Note: This is just reference. Please contact us to get price and details.