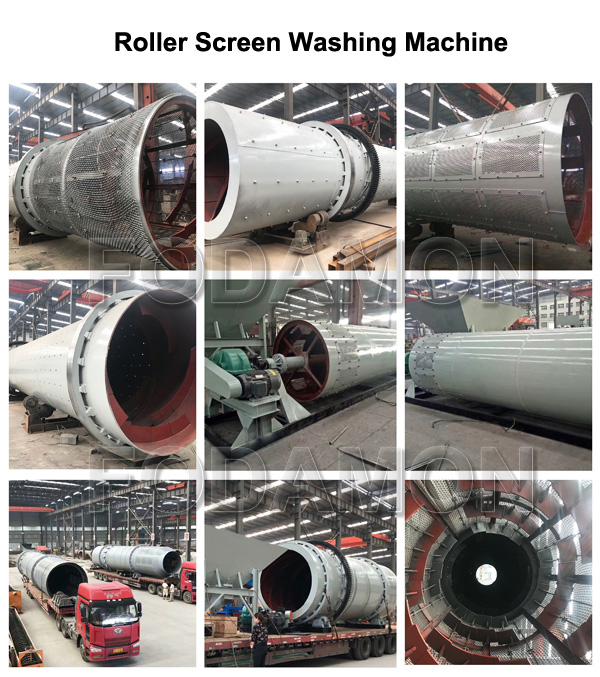

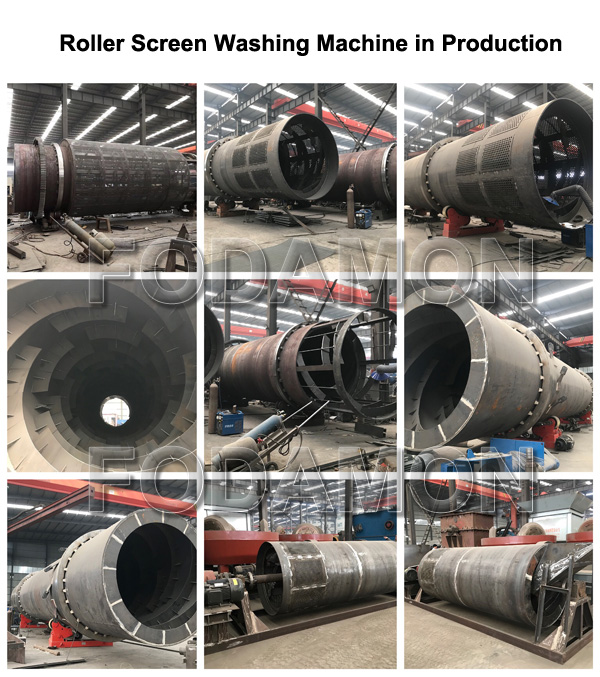

Roller Screen Washing Machine

Applied Materials:

Various ore, Lime, Stone, etc.

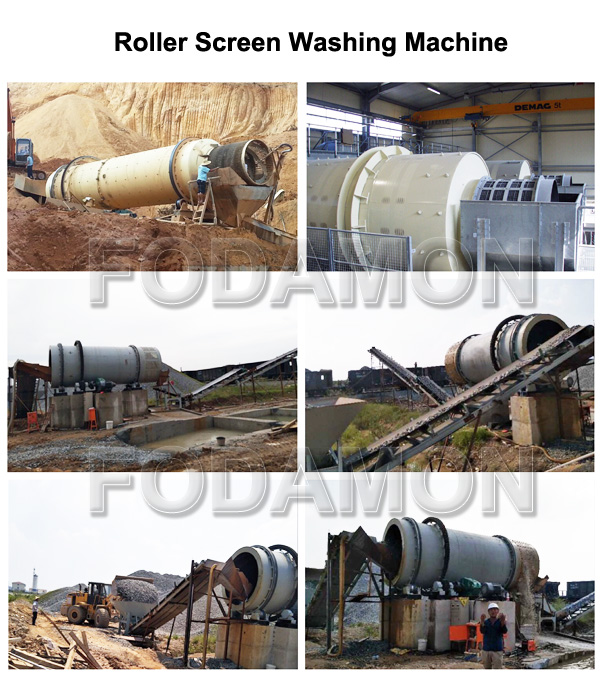

Applications:

Widely used in a variety of difficult to wash large ore

If you want to learn more about our roller screen washing machine, Leave a Message!

Introduction of Roller Screen Washing Machine

Roller screen washing machine is also called drum screen machine and rotary screen machine. It is a new multi-purpose water washing equipment with mixing function, cleaning function and screening function. The roller screen washing machine can not only clean the raw materials preliminarily, but also screen the raw materials according to the size of particles. Roller screening washing can solve the problem of water cleaning operation of various sands, stones and ores, such as the user’s raw materials with large soil content, high clay viscosity, which are not easy to dissolve in water, large particles and fine particles mixed together, but need to be cleaned and then graded. It can be widely used in ore dressing plants, stone yards, sand washing yards, mixing stations, precast slab factories and beam making yards Work place to be washed and screened.

Advantages of Fodamon Roller Screen Washing Machine

1. The installation foundation is simple. Because the whole equipment is a box frame structure, there is only one flat floor and the sewage reuse sedimentation tank. The ground is best hardened for cleaning.

2. High integrity. Except for the finished material stacker belt conveyor, all the systems are integrated into a whole framework, which not only ensures the integrity of the equipment, but also leaves a moderate maintenance and inspection space, convenient and safe.

3. Working reliability. The core stone washing system adopts the mixing principle of the mixer. The raw materials are rolled, pushed and rubbed by the continuous spiral blades in the mixing drum. The stone materials can be separated by soaking and rubbing in a short time, and the sludge content can be less than 0.5% before the stone is discharged.4. Use economy. Storage hopper capacity up to 8M, so that the loader reasonable arrangement of the main equipment (such as mixing station) and the loading time of the stone washing machine, to avoid the loader in different feeding points and frequent shifts between raw materials, hopper mouth width of 3.2 meters, but also easy loading loader, reduce labor intensity.

Working Principle

In the drum screening machine, the raw material enters the drum through the inner spiral of the fast guide area, and first passes through the spiral blades on the inner wall of the rotating drum to continuously mix, rub and rub, so as to achieve the cleaning effect of crushing and dissolving the mud in the raw material into the water and separating the mud and sand. With the advance of the rotary cylinder, the raw mud moves slowly to the screening dehydration area. The mud and sand produced by the screen washing in the raw material slurry are discharged through the upper drainage outlet of the cylinder in the dehydration area, collected by the chute, and transported to the spiral sand washing machine for sand cleaning; while the large particle raw materials larger than the drainage outlet of the dehydration area move slowly to the discharge end with the continuous advancement of the blades in the cylinder, discharged from the discharge outlet of the roller screen washing machine, and transported through the gravel belt conveyor Send them to the finished product pile. Our company suggests that users can make full use of the structural features of the peripheral drive of the roller screen washer. A high-pressure water spray pipe through the feed end and the discharge end is added to the cylinder of the screen washer. It can not only improve the cleaning effect of the roller screen washing machine, but also improve the utilization of clean water.

If you want to learn more about our roller screen washing machine, Leave a Message!

If you want to learn more about our roller screen washing machine, Leave a Message!

Technical Data

| Model | Feeding size (mm) |

Slurry barrel length(mm) | Sieve cylinder length(mm) | Hole size of screening cylinder (mm) |

Power (kw) |

Rotary speed of spiral (r/min) |

Capacity (t/h) |

| Φ1.5×6m | 250 | 4000 | 2000 | 5-20 | 11 | 12.5 | 30-60 |

| Φ1.8×9m | 300 | 6000 | 3000 | 5-20 | 15 | 10.3 | 50-100 |

| Φ2.0×11m | 350 | 8000 | 3000 | 5-20 | 18.5 | 9.2 | 80-150 |

| Φ2.2×13m | 400 | 10000 | 3000 | 5-20 | 30 | 8.5 | 100-200 |

| Φ2.5×15m | 400 | 10000 | 5000 | 5-20 | 37 | 7.8 | 150-250 |

Note: This is just reference. Please contact us to get price and details.