Rod Mill

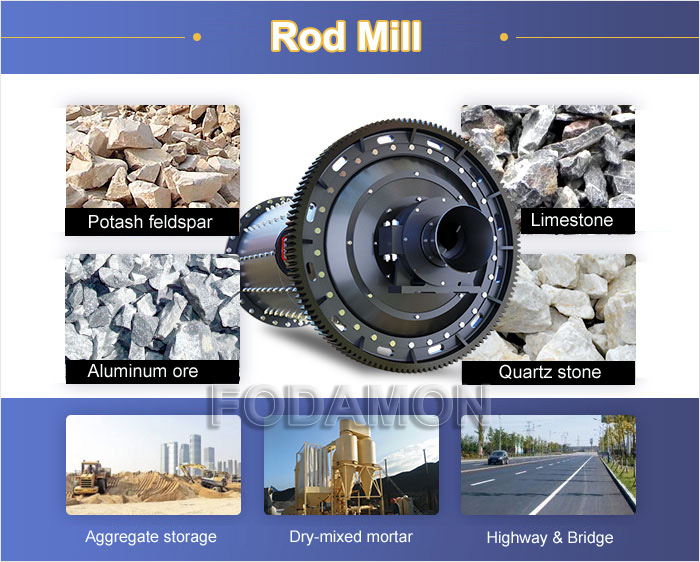

Applied Materials:

Quartzite, iron ore, copper ore, gold ore, cement clinker, pyrrhotite, hematite, limonite, construction waste and so on.

Applications:

Cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal beneficiation and glass ceramics.

If you want to learn more about our beneficiation equipment, Leave a Message!

Introduction of Rod mill

Introduction of Rod mill

The rod mill has two forms: dry and wet, and users can choose according to their actual conditions. Our factory adopts advanced controllable material import and export technology, combining the actual abrasive materials with appropriate abrasive, the traditional surface contact is changed to line contact, the granularity of the material is even more uniform and the output is higher, and it is widely used in the grinding operation with high uniformity of the wear resistance, chemical industry, metallurgy, glass and other industries. In recent years, it is also used for sand making in building sand.

Use of Rod Mill

1. In order to prevent the damage caused by over crushing, rod grinding is often used in the gravity or magnetic separation plants of tungsten tin ore and other rare metal ores, as well as quartz sand plants.

2. When two-stage continuous grinding is used, if the first stage is from 20-6mm to 3-1mm, and rod mill is used as the first stage grinding equipment, the production capacity is larger and the efficiency is higher.

3. In some cases, rod mill can replace short head cone crusher for fine crushing.

Working Principle

The rod mill is driven by the motor through the reducer and the surrounding large gear or by the low speed synchronous motor direct rod mill over the surrounding large gear to drive the gear and drive the cylinder to turn. The tube is equipped with a suitable grinding medium – steel bar. Under the action of centrifugal force and friction force, the grinding medium is raised to a certain height, dropping down or falling down. The grinded material is continuously entered into the cylinder by the inlet, and is crushed by the moving grinding medium, and the product is discharged through the overflow and continuous power supply to carry out the next operation.

If you want to learn more about our beneficiation equipment, Leave a Message!

If you want to learn more about our beneficiation equipment, Leave a Message!

Technical Data

|

Model |

Shell Specifications (mm) |

Shell rotation speed |

Feeding size |

Discharging size |

Processing capacity |

Power |

Total weight |

|

|

Diameter |

Length |

|||||||

|

FDM0918 |

900 |

1800 |

36-38 |

≤25 |

0.833-0.147 |

0.62-3.2 |

18.5 |

5.9 |

|

FDM0924 |

900 |

2400 |

36 |

≤25 |

0.833-0.147 |

0.81-4.3 |

22 |

6.7 |

|

FDM1224 |

1200 |

2400 |

36 |

≤25 |

0.833-0.147 |

1.1-4.9 |

30 |

13.9 |

|

FDM1530 |

1500 |

3000 |

29.7 |

≤25 |

0.833-0.147 |

2.4-7.5 |

75 |

19.8 |

|

FDM1830 |

1830 |

3000 |

25.4 |

≤25 |

0.833-0.147 |

4.8-11.6 |

130 |

34.9 |

|

FDM2130 |

2100 |

3000 |

23.7 |

≤25 |

0.833-0.147 |

14-35 |

155 |

46.5 |

|

FDM2136 |

2100 |

3600 |

23.7 |

≤25 |

0.833-0.147 |

19-43 |

180 |

48.7 |

|

FDM2430 |

2400 |

3000 |

21 |

≤50 |

0.833-0.147 |

25-65 |

245 |

59.7 |

|

FDM2736 |

2700 |

3600 |

20.7 |

≤50 |

0.833-0.147 |

32-86 |

380 |

92.5 |

|

FDM2740 |

2700 |

4000 |

20.7 |

≤50 |

0.833-0.147 |

32-92 |

400 |

95 |

|

FDM3245 |

3200 |

4500 |

18 |

≤50 |

0.833-0.147 |

64-180 |

630 |

149 |

Note: This is just reference. Please contact us to get price and details.