Linear Screen

Applied Materials:

Abrasives, quartz sand, refractory materials, machine sand, magnetic materials, glass, activated carbon, steel shots, etc.

Applications:

Mining, metallurgy, refractory, cement, coal, glass, ceramics, electricity and other industries.

If you want to learn more about our linear screen, Leave a Message!

Introduction of Linear Screen

Introduction of Linear Screen

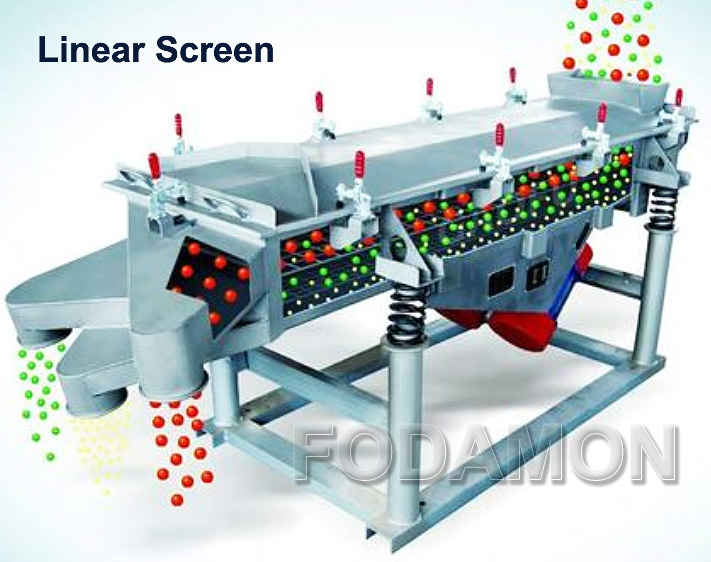

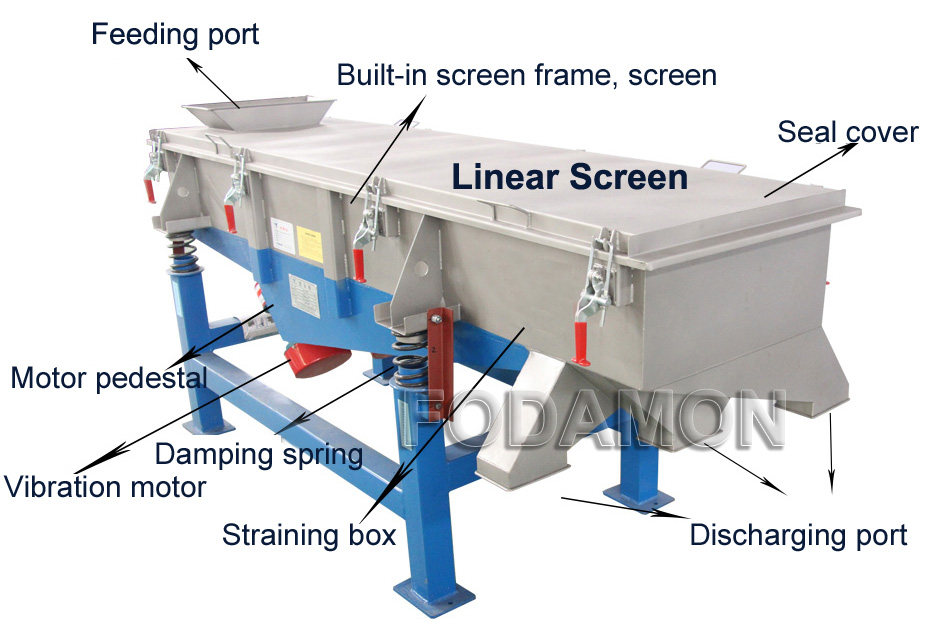

Linear vibrating screen is a kind of multi-functional screening equipment. This kind of linear vibrating screen is mainly customized according to the materials you screen, which will be more reasonable. It is composed of vibration motor, screen box, screen, vibration transmission body and vibration damping device. It is suitable for screening various dry powder materials with particle size of 0.074-5mm, moisture content less than 70% and no viscosity. The maximum feeding particle size is not more than 10 mm.

Working Principle

Working Principle

When two vibration motors longitudinally mounted on the screen body are operated relatively, the eccentric masses at both ends of the two vibration motors generate a rated exciting force, and the exciting forces generated in the lateral direction cancel each other due to the relative operation of the motor. The longitudinal exciting force is transmitted to the entire screen box through the vibration absorbing body, and the screen surface is vibrated, so that the material on the screen surface is subjected to the exciting force and jumps on the screen surface toward the discharge product, which is smaller than the mesh hole. The material falls through the sieve hole and falls to the lower layer, and flows out from the discharge port after continuous jumping. Since the screening process is reasonable, after the material is classified by the vibrating sieve, several materials of different particle sizes can be obtained, and the material classification operation is completed.

If you want to learn more about our linear screen, Leave a Message!

If you want to learn more about our linear screen, Leave a Message!

Technical Data

|

Model |

Nominal size(mm) |

Material size(mm) |

Bevel angle(°) |

Amplitude(mm) |

Layer(s) |

Power(kw) |

|

FDM520 |

500×2000 |

0.074~10 |

0°~7° |

|

1~5 |

2×(0.4~0.75) |

|

FDM525 |

500×2500 |

2×(0.4~0.75) |

||||

|

FDM530 |

500×3000 |

2×(0.75~1.1) |

||||

|

FDM535 |

500×3500 |

2×(0.75~1.1) |

||||

|

FDM1020 |

1000×2000 |

2×(0.75~1.5) |

||||

|

FDM1025 |

1000×2500 |

2×(1.1~1.5) |

||||

|

FDM1030 |

1000×3000 |

2×(1.5~1.8) |

||||

|

FDM1035 |

1000×3500 |

2×(1.5~2.2) |

||||

|

FDM1040 |

1000×4000 |

2×(1.5~2.2) |

||||

|

FDM1225 |

1200×2500 |

2×(1.5~2.2) |

||||

|

FDM1230 |

1200×3000 |

2×(1.8~3) |

||||

|

FDM1235 |

1200×3500 |

2×(1.8~3) |

||||

|

FDM1530 |

1500×3000 |

2×(2.2~3) |

||||

|

FDM1535 |

1500×3500 |

2×(2.2~3) |

||||

|

FDM1540 |

1500×4000 |

2×(2.2~4) |

Note: This is just reference. Please contact us to get price and details.