Spring Cone Crusher

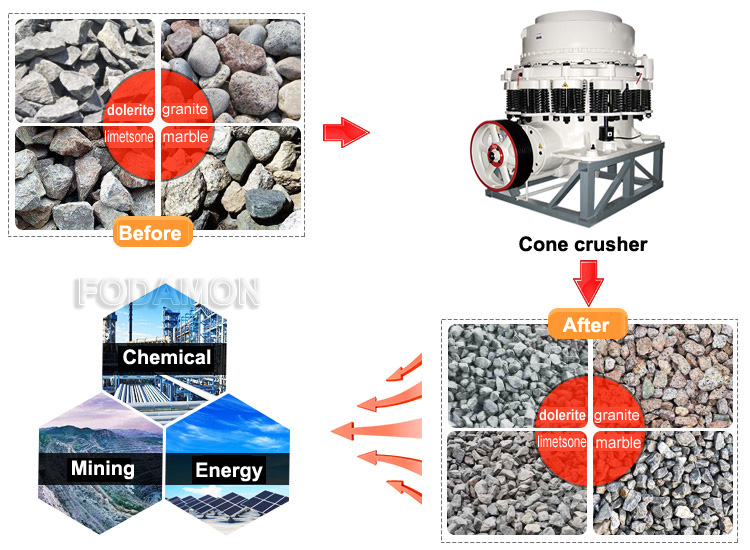

Applied Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Applications:

Metallurgy, building materials, road construction, chemical and silicate industries.

If you want to learn more about our crushing equipment, Leave a Message!

Introduction of Spring Cone Crusher

Introduction of Spring Cone Crusher

This series of crushers is suitable for crushing all kinds of ores and rocks with medium hardness and above. It has the characteristics of reliable structure, high production efficiency, convenient adjustment and economical use. The spring safety system is an overload protection device, which can make the foreign iron block pass through the crushing chamber without jeopardizing the machine, and adopts two kinds of sealing forms of dry oil or water to isolate the stone powder from the lubrication to ensure reliable operation. This series of crusher is divided into three types: coarse crusher cone crusher, medium crush cone crusher and fine crusher cone crusher. The standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for fine crushing. Can be purchased according to different needs of users.

The spring cone crusher produced by our factory is divided into ordinary spring cone crusher and composite spring cone crusher.

Working Principle

Working Principle

If you want to learn more about our crushing equipment, Leave a Message!

If you want to learn more about our crushing equipment, Leave a Message!

Technical Data

|

Model |

Diameter of moving cone |

Discharging size |

Max. Feeding size (mm) |

Capacity |

Power |

Weight |

Overall size (mm) |

|

PYB-600 |

600 |

12-25 |

65 |

15-25 |

30 |

5.5 |

1740×1225×1940 |

|

PYD-600 |

600 |

3-13 |

36 |

5-23 |

30 |

5.5 |

1740×1225×1940 |

|

PYB-900 |

900 |

15-50 |

115 |

50-90 |

55 |

10.18 |

1990×1640×2380 |

|

PYZ-900 |

900 |

5-20 |

60 |

20-65 |

55 |

10.19 |

1990×1640×2380 |

|

PYD-900 |

900 |

3-13 |

40 |

15-50 |

55 |

10.27 |

1990×1640×2380 |

|

PYB-1200 |

1200 |

20-50 |

145 |

110-200 |

110 |

24.7 |

2805×2300×2980 |

|

PYZ-1200 |

1200 |

8-26 |

100 |

50-150 |

110 |

25 |

2805×2300×2980 |

|

PYD-1200 |

1200 |

3-15 |

50 |

18-105 |

110 |

25.6 |

2805×2300×2980 |

|

PYB-1750 |

1750 |

25-60 |

215 |

280-480 |

155-160 |

50.6 |

3610×2950×4185 |

|

PYZ-1750 |

1750 |

10-30 |

185 |

115-320 |

155-160 |

51 |

3610×2950×4185 |

|

PYD-1750 |

1750 |

5-15 |

85 |

75-230 |

155-160 |

50.5 |

3610×2950×4185 |

|

PYB-2200 |

2200 |

30-60 |

300 |

590-1000 |

260-280 |

84 |

4790×3430×5080 |

|

PYZ-2200 |

2200 |

10-30 |

235 |

200-580 |

260-280 |

85 |

4790×3430×5080 |

|

PYD-2200 |

2200 |

5-16 |

110 |

120-370 |

260-280 |

85 |

4790×3430×4852 |

|

Model |

Discharge size |

Max.feed size |

Capacity (t/h) |

Power (kw) |

Weight (kg) |

|

|

900 |

PSGB-0910 |

9-22 |

85 |

45-91 |

75 |

9980 |

|

PSGB-0917 |

13-38 |

150 |

59-163 |

|||

|

PSGB-0918 |

25-38 |

150 |

118-163 |

|||

|

PSGD-0914 |

3-13 |

35 |

27-90 |

10530 |

||

|

PSGD-0906 |

3-16 |

65 |

27-100 |

|||

|

PSGD-0907 |

6-19 |

85 |

59-129 |

|||

|

1300 |

PSGB-1313 |

13-31 |

115 |

109-181 |

160 |

22460 |

|

PSGB-1321 |

16-38 |

178 |

132-253 |

|||

|

PSGB-1324 |

19-51 |

205 |

172-349 |

|||

|

PSGB-1325 |

25-51 |

220 |

236-358 |

|||

|

PSGD-1306 |

3-16 |

54 |

36-163 |

22590 |

||

|

PSGD-1308 |

6-16 |

76 |

82-163 |

|||

|

PSGD-1310 |

8-25 |

89 |

109-227 |

|||

|

PSGD-1313 |

16-25 |

113 |

209-236 |

|||

|

1600 |

PSGB-1620 |

16-38 |

178 |

181-327 |

220 |

43270 |

|

PSGB-1624 |

22-51 |

205 |

258-417 |

|||

|

PSGB-1626 |

25-64 |

228 |

299-635 |

|||

|

PSGB-1636 |

38-64 |

313 |

431-630 |

|||

|

PSGD-1607 |

5-13 |

60 |

90-209 |

43870 |

||

|

PSGD-1608 |

6-19 |

76 |

136-281 |

|||

|

PSGD-1613 |

10-25 |

113 |

190-336 |

|||

|

PSGD-1614 |

13-25 |

113 |

253-336 |

|||

Note: This is just reference. Please contact us to get suitable solution and competitive price.