The wear of hammer head of hammer crusher is inevitable, but if the wear is too fast and the replacement frequency is too high, it is necessary to check whether there are problems in the equipment itself or operation. According to Fodamon engineer’s analysis, the main factors affecting the wear of the hammer head are: the material, manufacturing quality and structural design of the hammer head, the technical design of the crusher, the feeding situation and the clearance of each part in the structure, etc.

01 Impact of hammer head material

Generally speaking, the greater the hardness of the hammer, the greater the wear resistance. To improve the wear resistance of the hammer, it is necessary to increase its hardness, but with the increase of hardness, the impact toughness of the hammer will decrease. Therefore, how to give consideration to the appropriate hardness and good impact toughness of the hammer is the key to improve the wear resistance of the hammer.

Hammer commonly used materials are: high manganese steel, high chromium cast iron, low carbon alloy steel.

High manganese steel has good toughness, good processability and low price. Its main feature is that under the action of large impact or contact stress, the surface layer will work hardening rapidly. Its work hardening index is 5-7 times higher than other materials, and its wear resistance is greatly improved. However, if the impact force is not enough or the contact stress is small, the surface can not be hardened rapidly, and the wear resistance of high manganese steel can not be fully developed.

High chromium cast iron is a kind of wear-resistant material with excellent wear resistance, but it has low toughness and is prone to brittle fracture. In order to ensure the safe operation of high chromium cast iron hammers, people have developed composite hammers, that is, high chromium cast iron is inlaid on the head of high manganese steel or low alloy steel hammers, or the working part of hammers is made of high chromium cast iron, and the handle part is made of carbon steel, The advantages of the two materials are brought into full play to overcome the disadvantages of single material and meet the performance requirements of hammer. However, the manufacturing process is complex and the process requirements are strict.

Low carbon alloy steel is mainly alloy structural steel containing chromium, molybdenum and other elements, with high hardness and good toughness. Its matrix structure includes martensite, bainite or bainite + martensite composite structure. Under the same working conditions, the service life of the hammer is at least twice as long as that of the high manganese steel hammer. However, the quenching and tempering heat treatment of hammer head is the key. After quenching and tempering heat treatment, not only the overall tensile strength is required to be more than 850mpa, but also considerable plasticity and toughness are required.

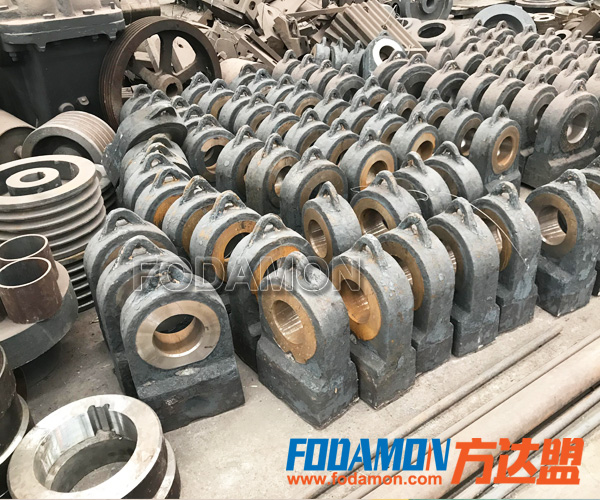

02 Manufacturing quality of the hammer

The manufacturing process of hammer head is also the key factor to determine its service life. If there are defects in the surface or internal manufacturing of the hammer head, such as shrinkage and cracks, it will not only reduce the performance of the hammer head, but even cause the hammer head to break. Therefore, reasonable casting and heat treatment process must be established in hammer production.

For example, for high chromium cast iron hammerhead, measures such as vertical casting, rational use of external chill and strict control of casting temperature should be adopted, so that the hammerhead can have good solidification sequence and feeding conditions during casting, thus obtaining dense internal structure and weakening the phenomenon of coarse grain.

03 Structure design of the hammer head

The mechanical properties and internal microstructure of hammers with different structures and geometric shapes are very different, which has a great influence on the wear resistance, especially for hammers with large thickness and size. The thicker the hammer head is, the harder it is to harden, and the worse its wear resistance is.

As the internal anti-wear performance of the hammerhead is obviously lower than that of the surface, it can only be improved by reasonable casting and heat treatment process for the hammerhead with larger thickness. However, this method is limited to improve the anti-wear performance of the hammerhead. The best way is to optimize the structure of the hammerhead without changing the impact kinetic energy and strength of the hammerhead, On the one hand, it can improve the utilization rate of the hammer, on the other hand, it can reduce the influence of the structure on the heat treatment performance and avoid the decline of the wear resistance of the hammer.

The remaining three factors affecting the service life of hammers will be explained in the next section.