Machined sand is relative to natural sand such as river sand. Natural sand is mainly attacked by natural forces, such as river sand, sea sand, mountain sand and so on. Machine-made sand refers to rock particles with particle size less than 4.75 mm made by mechanical crushing and screening after soil removal.

Making machine-made sand from limestone can effectively improve the mineral yield of limestone blocks, reduce the discharged amount of limestone waste residue, and achieve remarkable energy saving and emission reduction effect.

Limestone mechanism sand production process: Limestone processing is mainly grinding, grading and production of lime, hydrated lime, precipitated calcium carbonate, carbon dioxide and so on. Limestone generally adopts dry crushing technology. For metallurgical and road limestone, the ore can be crushed and screened.

Limestone or limestone raw ore grade can generally meet the requirements of various industrial departments, generally only need to carry out simple ore washing, that is, the use of washing – crushing – screening or classification methods to treat limestone or limestone ore.

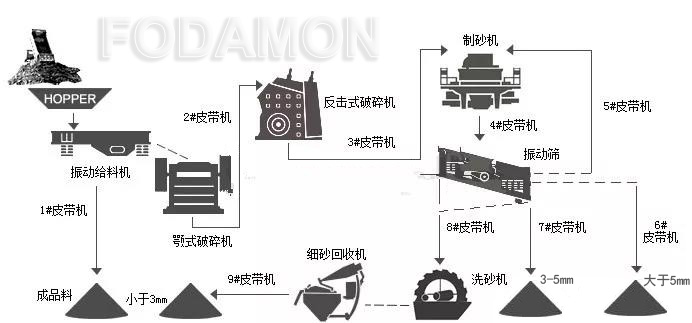

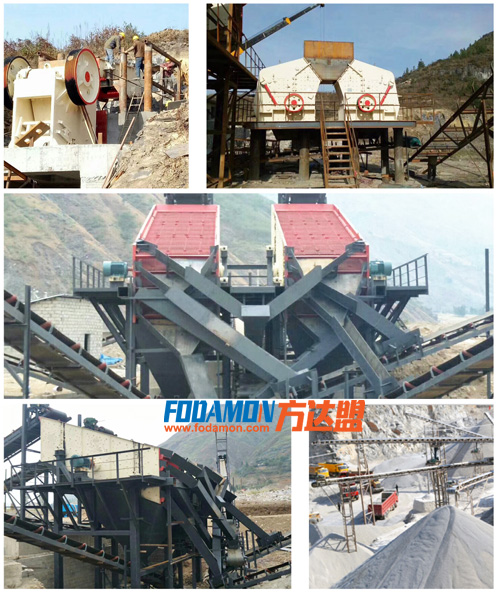

The technological process of manufactured sand production is as follows: feeding → crushing → medium and fine crushing → screening → sand making → screening → sand washing → finished products.

The required equipment includes vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, sand making machine, sand washing machine, belt conveyor and fine sand recovery machine, etc.

Limestone mechanism sand advantage

Limestone machine-made sand is made from waste materials, slag and lime powder from limestone yard. It is made by mechanical crushing, washing and screening. The limestone machine-made sand processed according to the above process has the following advantages:

- Machine-made sand can effectively and steadily control sand particles according to national standards and engineering quality requirements, and meet engineering technical requirements.

- The granularity and fineness modulus of manufactured sand can be adjusted. According to the needs of the project, the fine modulus and granularity of manufactured sand can be adjusted according to the good points of the base material and the requirements of concrete.

- Machine-made sand particles have many edges and corners and rough surface, which are beneficial to bonding with cementitious materials such as cement and improving the strength of concrete.

- The production of machine-made sand can be combined with the production technology of crushed stone, which is conducive to the comprehensive utilization of good mineral resources and the reduction of pollution, thus greatly reducing the production cost of machine-made sand.

What kind of lithological rocks should be used to prepare sand aggregates in different areas also need to be adapted to local conditions, depending on the specific situation! If you have the need of sand making, please contact us. Engineers of Fodamon will design an economical and reasonable sand-making process for you according to your stone properties and requirements.