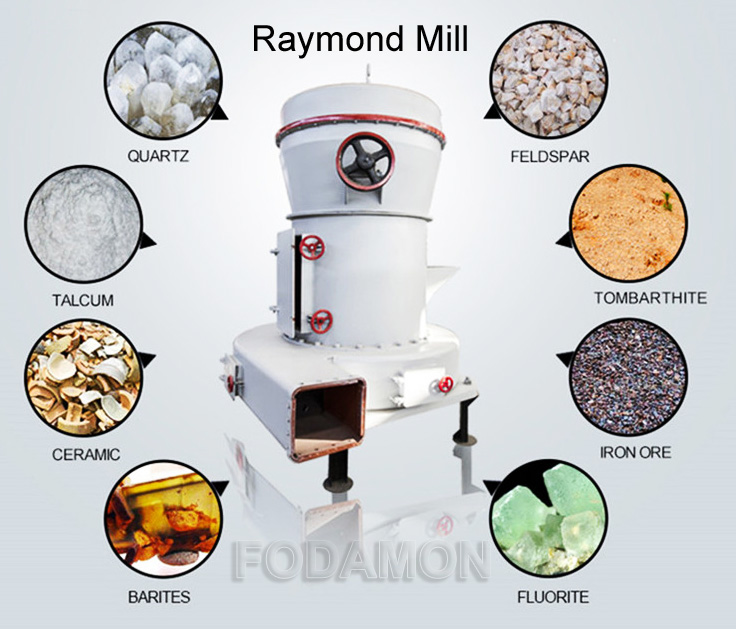

Raymond mill is one of the widely used equipment in grinding industry. According to the statistics of the competent department of the industry, Raymond Mill occupies more than 70% of the domestic grinding equipment. However, with the production going on, there will be a decrease in the powder yield, which will affect the production efficiency. Fodamon engineers will take you to know more about the causes and solutions for the reduction of discharge rate of Raymond mill.

The reason for the reduction of the yield of Raymond mill?

The powder locking device is not tightly sealed

If the sealing work of the powder locking device is not in place during the milling process of Raymond pulverizer, the phenomenon of powder backward suction will be formed, resulting in no powder or less powder output. Therefore, the sealing of powder locking device shall be checked and the sealing degree shall be adjusted.

The analyzer didn’t work

The analyzer of Raymond mill is responsible for analyzing the size of finished powder, whether it meets the standard of finished product and whether it needs to be grinded again. If the blade of analyzer is seriously worn, it can not play the role of grading, which will cause the powder to be too coarse or too fine. In this case, it can be solved by replacing a new blade.

The fan is not adjusted properly

If the air volume of Raymond mill fan is not adjusted properly and the air volume is too large, it will cause abnormal powder discharge of the mill. If the air volume is too small, the powder will be too fine. If there is no abnormality in other conditions, the air volume of the fan should be adjusted to correct the powder size.

Failure of the blade

The blade of Raymond Mill is responsible for shoveling the material. When the blade is used for a period of time or the quality is not strong enough, the wear is large, the material cannot be shoveled, and it will cause no powder or less powder. A new blade needs to be replaced in order to ensure the normal operation of the equipment.

So after excluding the above reasons, how can we increase the powder yield and output? Generally speaking, in order to make a large amount of powder and a high output in the production process of Raymond Mill, there are the following requirements:

Scientific and reasonable collocation

When Raymond mill is working, on the one hand, it is necessary to consider whether the equipment model selection can meet the daily production demand and avoid overload of the equipment. On the other hand, materials should be selected with moderate hardness as far as possible, which is more suitable for Raymond mill materials, so as to prevent the material hardness from being too large, which is difficult to achieve milling operation and block up at the outlet, resulting in difficulty in powder discharge.

Reasonably select the speed of the host machine and increase the grinding force of the host machine

Considering the load-bearing capacity of the host motor is a factor to improve the production efficiency of the pendulum mill. Increase the kinetic energy of the mill, adjust the belt or replace it with a new one.

Regular maintenance

The Raymond mill should be overhauled after being used for a period of time. Meanwhile, the wearing parts such as grinding roller, grinding ring and blade should be repaired and replaced. Before and after using the grinding roller device, the connecting bolts and nuts should be carefully checked to see whether there is looseness and whether the lubricating grease is sufficient. In addition, when the grinding roller device is used for more than 500 hours or so, the rolling in the roller sleeve shall be adjusted The bearing must be cleaned and the damaged parts should be replaced in time.