Impact crusher has the advantages of simple structure, low price and good crushing particle shape, which is beneficial to the separation of mineral monomers (especially embedded minerals) and convenient maintenance. In the mine crushing production line, the impact crusher is generally used as the second crusher to crush the materials to the required particle size. The capacity of the impact crusher will directly affect the economic benefits of the entire production line. So, how to effectively increase the capacity of the impact crusher? The analysis and suggestions of Fodamon engineers are as follows.

- Reasonably reduce the humidity of materials

If the moisture contained in the material is large, the material is easy to adhere in the crushing cavity, and it is also easy to block during the cutting process, reducing the production capacity of the impact crusher. Therefore, for materials with a large moisture content, drying or drying in advance can be adopted to reasonably reduce the humidity of the materials and increase the production capacity of the impact crusher. - Pre-screen materials in advance

If the material before crushing contains a large amount of large pieces of ore, it will inevitably increase the crushing time of the material in the crushing chamber, and the capacity of the impact crusher will be reduced to a certain extent. And if the material before crushing contains a lot of fine powder, it will also reduce the capacity of the impact crusher. Because these fine powders will easily adhere, affecting the transportation and cutting. The materials are pre-screened in advance, and the bulk and powder materials are screened out for processing, so that the materials entering the crushing chamber are more in line with the design requirements of the impact crusher, and effectively increase the capacity of the impact crusher. - Reasonably increase the main motor power

Within the range of rated motor power, the larger the main motor power, the higher the production efficiency of the impact crusher and the higher the production capacity. Therefore, in production, the power of the main motor can be increased within the allowable range to increase the capacity of the impact crusher. - Properly increase the rotor speed

The speed of the rotor is one of the important working parameters of the impact crusher. It plays a decisive role in the crusher’s production capacity, product size and crushing ratio. Tests have shown that with the increase in rotor speed, the production capacity and crushing ratio of the impact crusher have increased significantly, and the product particle size will be relatively fine. However, with the increase of the rotor element, the power consumption also increases, the abrasion of the hammer accelerates, and a certain production cost is increased. Therefore, the high rotation speed of the rotor cannot be pursued blindly in production, and the increase of the rotation speed should be appropriate. - The angle of the reaction plate should be appropriate

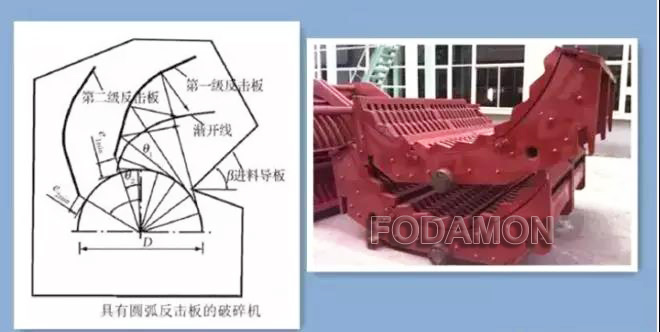

At present, there are two kinds of counterattack plates in the market: the broken line counterattack plate and the arc counterattack plate. The angle of each stage of the impact plate has a great influence on the effective crushing force of the impact plate, and also on the impact and shear crushing of the material.

The broken line type impact plate has a simple structure, but it can’t guarantee the most effective impact crushing of ore. therefore, when purchasing and debugging the impact crusher, we must pay attention to the angle of the impact plate, try to make the material perpendicular to the impact plate when it collides with the impact plate, and improve the capacity of the impact crusher.

The arc-shaped impact plate is more commonly used with involute linear structure. This structural form features that at each point of the impact plate, the ore is impacted in a vertical direction, with higher crushing efficiency and productivity.