Cone crusher is one of the popular medium and fine crushing equipment, which is suitable for crushing all kinds of medium hard and hard materials. The output of cone crusher is affected by many factors. If these factors are selected properly, the output of the equipment will be increased. This paper shares 7 factors that affect the output of cone crusher.

Rotating speed of moving cone

The rotation speed of moving cone is an important factor affecting the output of crusher. If the rotation speed is too slow, the material will slide through the crushing chamber along the contour of the moving cone liner plate, and the time it takes to pass through the crushing chamber is long, so the output is certainly low, and the particle size of the product will deteriorate. However, if the rotation speed is too fast, the material will hardly discharge downward. Even if it is broken, there will be stagnation time after the material is broken, which will definitely cause blockage So there is an optimal rotational speed.

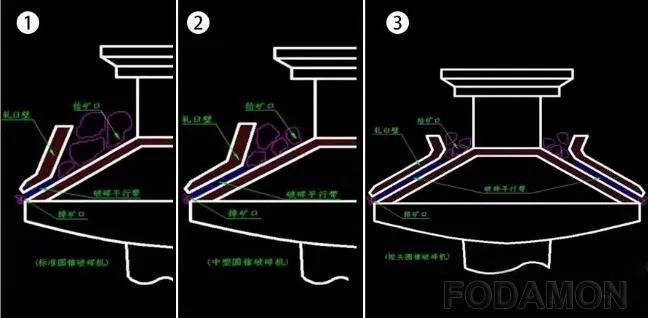

Length of parallel area

The starting point of the parallel zone is the plug point of the crushing chamber, and the shorter the length of the parallel zone, the lower the position of the blocking point. At this time, it is equivalent to increasing the actual diameter of the dynamic cone of the crushing chamber, resulting in higher output, but the quality of the crushing products will be worse. The longer the parallel zone is, the higher the position of the blocking point will be. At this time, the output will be reduced, but the product quality will be improved.

The parallel zone is longer, and the feed and discharge outlets are small, so fine product size can be obtained. Generally, the short head with long parallel band is put after the middle crushing as fine crushing. Because of the short parallel belt of the standard type, the crushing product is coarse and the output is high. It is generally placed after the coarse crushing, that is, after the jaw crusher or the rotary crusher, as the intermediate crushing.

Base angle of moving cone

The base angle of the moving cone determines the inclination angle of the moving cone. The larger the base angle of the moving cone is, the easier it is for the material to fall freely. However, in this way, the number of times when the material is squeezed and crushed through the crushing chamber will be less. Although the output increases, the quality of the product will be reduced. When the base angle of the moving cone becomes smaller, the surface of the moving cone will become gentle, and the material will slide down along the movable cone liner, The output is lower, but the quality of the broken products is better. In addition, the size of the moving cone base angle will also determine the height of the fixed point of the crusher. When the moving cone bottom angle is larger, the fixed point position will be higher, and the material will be easier to fall freely in the crushing chamber. At this time, the laminating effect is obvious, and the yield is increased. When the moving cone base angle is smaller, the fixed point position will be decreased, and at this time The lamination effect is not good and the output is reduced.

Precession angle

The size of precession angle will directly determine the eccentricity of crusher and the swing stroke of discharge port. When the precession angle increases, the eccentricity of the crusher and the swing stroke of the discharge port will become larger, and the materials are easier to fall down freely, so the output will be increased. However, the number of times the materials are squeezed and crushed in the crushing chamber will be reduced, resulting in the decline of the product quality; when the feed angle is smaller, the eccentricity of the crusher and the swing stroke of the discharge port will become smaller, leading to the material passing through the crushing chamber As time goes on, the output will be reduced, but the material is more likely to be broken in the crushing chamber, which improves the quality of the product. Therefore, on the basis of ensuring the product quality, reducing the precession angle will increase the yield of the product.

Dimension of closed edge discharge port

The output of cone crusher is determined by the size of closed edge discharge port. When the size of closed edge discharge port becomes larger, the output of cone crusher increases, but the quality of broken products becomes worse, and the content of needle and flake materials in products increases; when the size of closed edge discharge port becomes smaller, the output of cone crusher becomes smaller, but the quality of crushing products becomes better.

Material filling rate

The filling rate of materials has a very important relationship with the output of the crusher. When the filling rate of materials is too small, the materials can not fill each crushing layer, then the output will certainly decrease; when the filling rate is too large, the material will fill the crushing chamber full, but the material is compressed, it is not easy to carry out lamination crushing, and the material is not easy to pass through the crushing chamber, resulting in the output of the crusher is not High quality and poor quality. Therefore, in the feeding process, there is an optimal material filling rate.

Operation factors of crusher

The impact of crusher operation factors on the output is subjective and can be avoided completely, but if these subjective factors are not paid attention to, it will have a great impact on the output of the crusher. The operation factors affecting the crusher output include: whether the feeding is sufficient, whether the feeding granularity is uniform, etc. When the crusher is working, if the feeding is not enough, the crusher will be in the working state for nothing, resulting in a serious decline in output; if the feed particle size distribution is not uniform, or even the particle size difference is very large, the crushing force will be unreasonable, leading to serious liner wear, which will greatly affect the production of crushing products.