“Waste rock is a resource misplaced”. After processing, waste rock can be called high-quality gravel aggregate. If we want to realize “turning waste into treasure”, we need to adopt a feasible processing scheme to comprehensively recycle it. For the use of mine waste rock and tailings, many people know that they can be used to produce recycled sand and gravel aggregate, but they don’t know much about other uses. Today, Fodamon engineer will share 13 uses of mine waste rock and tailings.

(1) Sand aggregate

Gravel aggregate is the largest, indispensable and irreplaceable basic material for the construction of infrastructure projects such as buildings, roads and bridges. However, sand and gravel aggregates are non renewable resources, and thousands of years of mining has caused great damage to the earth’s environment. In the metal and non-metal mining industry, in the long-term mining and production process, the mine produces a large number of waste rocks and tailings. The use of these tailings resources can completely or partially replace the sand and gravel aggregate.

Many waste rocks in mines can be used as coarse and medium aggregates. The physical properties and chemical composition of rocks should be considered when evaluating aggregates. Both depend on the type of rock, but also consider the degree of fracture development and weathering. Among the physical properties, the one with high strength is certainly advantageous; In addition, the elastic modulus should be considered. The closer the elastic modulus is to the cement mortar, the better. At the same time, the waste rock used as aggregate shall not contain too much flake or fibrous rock debris. Generally speaking, limestone, fine sandstone, quartzite, granite with relatively fine crystallization, diorite, gneiss and basalt are suitable for aggregate. The concrete of some airport runways also requires basalt as aggregate, which is related to the highest strength of basalt in natural rock.

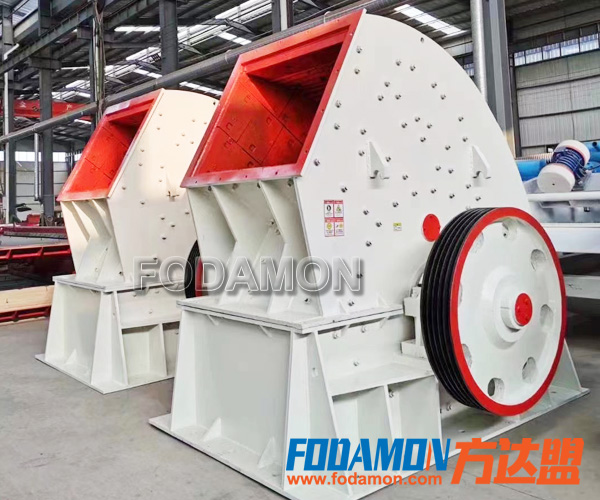

In the production of sand and gravel aggregate, jaw crusher, impact crusher, cone crusher, vibrating screen, belt conveyor, sand washing machine and other equipment are often used.

(2) Concrete fine aggregate

When using tailings as fine aggregate of concrete, the same requirements for coarse and medium aggregate shall also be considered. Generally speaking, tailings sand is better than sea sand, because sea sand often contains salt and chloride ions, which is easy to rust reinforcement, and the surface of tailings is rough and angular, which can increase the strength of concrete. However, the tailings shall be used as fine aggregate, requiring a certain particle size. When the particle size does not meet the requirements, the tailings shall be screened. Because the coarse sand makes the concrete dry, the viscosity decreases and the workability is not good; Ultra fine sand not only makes the concrete easy to separate, but also needs a large amount of water, thus increasing the amount of cement.

(3) Using waste rock as railway ballast

The requirement for railway ballast is that it is not fragile under vibration pressure. Of course, rocks with schistosity or bedding are not suitable for railway ballast, while limestone and basalt are more suitable for railway ballast.

(4) Cement mixture

Adding an appropriate amount of mixed materials into cement can not only improve some properties of cement, but also save the consumption of basic materials. Mixed materials are divided into filling and active materials. At present, blast furnace slag and fly ash have become common cement active mixtures. In fact, some tailings are also suitable for mixed materials, such as the tailings of vanadic ilmenite deposit in amphibolite. In addition, those with high content of amorphous substances in waste rock (or tailings), such as glassy volcanic rock, tuff, pumice, etc., can also be used as active mixed materials.

(5) Correction raw materials for cement

Iron correction raw material and silicon correction raw material. Tailings can also be used for these two raw materials. The tailings of some metal ores have high iron content and can be sold to cement plants as iron correction raw materials; The tailings of some iron ores contain both a large amount of silicon and iron, and can also be used as correction raw materials.

(6) It is used to produce all kinds of bricks

At present, coal gangue brick has become one of the main wall building materials to replace clay brick. It can not only burn gangue red brick, but also burn hollow brick. In fact, many shale waste rocks are also suitable for brick making, but the energy consumption is higher than gangue brick. In addition, non calcined gypsum tailings are used as raw materials. After grinding, they are mixed with a certain proportion of ground slag and fly ash. Under the action of composite activator, they can be used to produce Gypsum Tailings bricks, hollow blocks and other new wall materials.

In fact, many tailings can be used to manufacture steam curing brick / autoclaved brick. This kind of brick is made by cementing tailings with a certain gelling agent and curing them with steam, or even high-pressure steam.

Square brick is a kind of ceramic imitation stone product just used in China. It can have a variety of shapes and colors and can be combined into various patterns at will. Generally, it can be fired at 1200 ~ 1300 ℃ with 30 ~ 50% tailings and some ceramic raw materials and pigments.

(7) Reclaiming farmland with tailings pond

This technology is to turn the wasteland on the river beach into arable land. In arid areas such as North China and Northwest China, there are often many intermittent or semi intermittent rivers with wide beaches and narrow waterways even when it rains; There are a large number of river pebbles of different sizes on the beaches on both sides of the river, which can not be used as cultivated land. The method is to build a dam with a height of 3.5 ~ 5 meters with stones on the river beach, and the area of each pond is about 40 mu; The tailings are directly discharged into the pond. When the pond is full, it is then discharged into another new enclosed pond. For the pond filled with tailings, the river pebbles have been buried under the tailings and covered with about 25 cm of arable soil, which makes the pond become arable land. At present, it has been successfully applied in some areas.

(8) Landfill open pit with waste rock or / and tailings

Waste rock or tailings will be discharged into the existing open pit in the past, and then covered with a certain thickness of arable soil to make it arable. This is the method being adopted by some mines.

(9) As raw material for producing silica brick

Silica brick is an acid refractory, which is widely used in glass furnace, coke oven or hot blast furnace. Its load softening starting temperature is as high as 1640 ~ 1670 ℃. The requirement for silica brick raw materials is that the content of SiO2 shall not be less than 96%, and there shall not be too many impurities such as Al2O3, N2O and K2O. Some Kaolin Tailings fully meet this requirement; Moreover, in the waste rock of some mines, there are quartzite or quartz sandstone that can meet this requirement.

(10) For the production of calcium carbonate

Papermaking white mud, calcium carbide slag, phosphogypsum and alkali slag contain a large amount of calcium hydroxide or calcium oxide, which can be used as raw materials for the production of light calcium carbonate.

(11) Used as raw material of heavy calcium carbonate

Heavy calcium carbonate is mainly used as the main raw material or filler in plastics, rubber, glass, ceramics, toothpaste and other industries. It mainly takes calcite and dolomite as the main raw materials. Its requirements are high purity, low iron content, no sulfur and harmless to human body. There are fragments of large calcite vein or dolomite vein or pure marble and dolomite in the waste rock of some deposits, which can be selected from the waste rock as this raw material.

(12) Tailings reselection: recover valuable components from tailings

Carrying out tailings re concentration is an important measure to improve resource utilization and reduce tailings discharge. From the results of tailings re concentration, it can be seen that it not only improves the recovery rate of resources, but also brings great economic benefits to the enterprise.

In the field of mining, the industrial developed countries in the world have taken waste free mines as the development goal of mines and the comprehensive utilization degree of tailings as a symbol to measure a country’s scientific and technological level and economic development. The utilization rate of tailings abroad can reach more than 60%, and some European countries have been developing towards the goal of waste free mines.

River sand mining was banned and the sand and gravel industry was rectified. There was a shortage of sand and gravel and the price soared. The resource utilization of solid waste is particularly urgent. Its recycled materials can replace some artificial and natural sand and gravel aggregates to realize recycling, or will become a new opportunity.