Quartz is the most common and studied mineral in the earth’s crust, which mainly includes quartzite, quartz sandstone, vein quartz and quartz sand. Quartz sand plays an important role in glass industry, foundry industry, filler field and the production of metal silicon and organosilicon compounds. With the development of economy, higher requirements are put forward for the quality of quartz mineral products. Fodamon engineer has the following summary for quartz sand process.

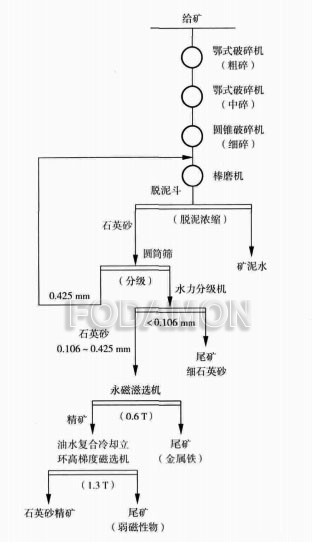

The process of producing quartz sand in quartz placer enterprises can be divided into wet process and dry process. Wet beneficiation is mainly used in China. Although the wet beneficiation processes are different, the general process flow is: three-stage crushing, wet grinding, classification and iron removal.

In addition to some natural quartz, quartzite, quartz sandstone and vein quartz ore need to be crushed. Crushing generally includes coarse crushing, medium crushing and fine crushing. Crushing equipment mainly includes jaw crusher, cone crusher, impact crusher, hammer crusher, vertical impact crusher, double roll crusher, etc. Wet grinding equipment mainly includes ball mill, rod mill, etc. Classification equipment mainly includes spiral classifier, trommel screen, hydrocyclone, high-frequency vibrating fine screen, etc. Iron removal equipment mainly includes iron remover, magnetic separator, water-cooled vertical ring high gradient magnetic separator, etc.

Wet process:

Wet beneficiation mainly uses mechanical scrubbing combined with magnetic separation, flotation, acid leaching and other processes to remove impurities, especially iron impurities, in the raw quartzite ore. The wet production yield is high. The main products of the wet process are 20-120 mesh wet sand. After pickling and flotation, the wet sand forms refined quartz sand with 60-140 mesh, which can be used for solar borosilicate glass collector tubes, medicinal glass and high-temperature pressing Production of special glass.

Dry process:

Dry production does not use water, saves energy, has no dust pollution, and the product has low iron content. The main process of the dry process is: the raw ore is coarsely crushed by a jaw crusher, medium crushed, after sieving to remove the soil, rod mill grinding, magnetic separation, coarse separation, fine separation, cyclone, among which coarse separation and fine separation The separation produces silica sand of 20-120 mesh, which can be used for the preparation of float flat glass. After the product of the dry process undergoes flotation processing, by-products such as 120 mesh fiber sand can be obtained.

The dry process is a mature process widely used by domestic quartz sand production enterprises. It can produce products with different particle sizes and different moisture content at any time according to the requirements of the enterprise. The equipment is large-scale, highly automated, without dust pollution, and the sewage can be settled and clarified. Recycling does not pollute the surrounding environment.

The beneficiation method of quartz sand shall be selected according to the actual situation.